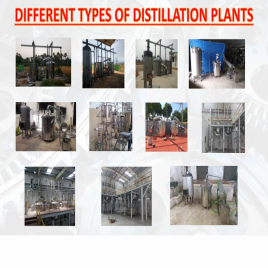

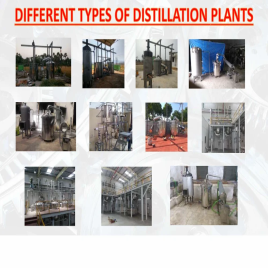

Distillation Units

SS 304 AROMATIC OIL STEAM DISTILLATION UNIT MANUFACTURER IN INDIA, Capacity: 500 liter

Brand:

Others

Price ₹

5,00,000.00

| General Details: | |

| Model | SS 304 AROMATIC OIL STEAM DISTILLATION UNIT MANUFACTURER IN INDIA, Capacity: 500 liter |

| Material | SS 304 |

| Capacity | 500 liter |

| Capacity | 500 liter |

| Others: | |

| Brand/Make | MECH O TECH |

| Country of Origin | Made in India |

| Recommended Order Quantity | 1 UNIT |

| Model Name/Number | MECH O TECH |

| Usage/Application | DISTILLATION |

Small Scale Essential Oil Extraction Machine, For Industrial, Capacity: 5 ton/day

Brand:

Others

Price ₹

1,75,000.00

| General Details: | |

| Model | Small Scale Essential Oil Extraction Machine, For Industrial |

| Capacity | 5 ton/day |

| Voltage | 240 V |

| Capacity | 5 ton/day |

| Others: | |

| Frequency | 50 Hz |

| No. of Screws | 50 L |

| Operation Type | Semi Automatic |

| Usage/Application | Industrial |

SS 304 Aromatic Oils Steam Distillation Plant, Capacity: 500 liter

Brand:

Others

Price ₹

7,00,000.00

| General Details: | |

| Model | SS 304 Aromatic Oils Steam Distillation Plant, Capacity: 500 liter |

| Material | SS 304 |

| Capacity | 500 liter |

| Capacity | 500 liter |

| Others: | |

| Brand/Make | MECH O TECH |

| Country of Origin | Made in India |

| Recommended Order Quantity | 1 Piece |

| Usage/Application | DISTILLATION |

SS 304 Lemongrass Oil Distillation Unit, Capacity: 500 liter

Brand:

Others

Price ₹

7,00,000.00

| General Details: | |

| Model | SS 304 Lemongrass Oil Distillation Unit, Capacity: 500 liter |

| Material | SS 304 |

| Capacity | 500 liter |

| Capacity | 500 liter |

| Others: | |

| Brand/Make | MECH O TECH |

| Country of Origin | Made in India |

| Recommended Order Quantity | 1 unit |

| Usage/Application | Steam Distillation |

SS 304 Palmarosa Oil Distilation Plant, For Distillation, Capacity: 500 liter

Brand:

Others

Price ₹

7,00,000.00

| General Details: | |

| Model | SS 304 Palmarosa Oil Distilation Plant, For Distillation, Capacity: 500 liter |

| Material | SS 304 |

| Capacity | 500 liter |

| Capacity | 500 liter |

| Others: | |

| Brand/Make | MECH O TECH |

| Country of Origin | Made in India |

| Recommended Order Quantity | 1 unit |

| Usage/Application | Distillation |

SS 304 Steam Cum Hydrodistillation Unit

Brand:

Others

Price ₹

1,00,000.00

| General Details: | |

| Model | SS 304 Steam Cum Hydrodistillation Unit |

| Material | SS 304 |

| Capacity | 500 liter |

| Capacity | 500 liter |

| Others: | |

| Brand/Make | MECH O TECH |

| Country of Origin | Made in India |

| Recommended Order Quantity | 1 UNIT |

| Usage/Application | STEAM DISTILLATION / HYDRO DISTILLATION / HYDROSOL |

SS 304 HYDRO DISTILLATION EQUIPMENT, Capacity: 500 liter

Brand:

Others

Price ₹

1,00,000.00

| General Details: | |

| Model | SS 304 HYDRO DISTILLATION EQUIPMENT, Capacity: 500 liter |

| Material | SS 304 |

| Capacity | 500 liter |

| Capacity | 500 liter |

| Others: | |

| Brand/Make | MECH O TECH |

| Country of Origin | Made in India |

| Recommended Order Quantity | 1 Piece |

| Usage/Application | DISTILLATION / HYDROSOL |

STEEL Hydrosol Distillation Machine, Capacity: 2000 LPH

Brand:

Others

Price ₹

1,75,000.00

| General Details: | |

| Model | STEEL Hydrosol Distillation Machine, Capacity: 2000 LPH |

| Material | STEEL |

| Capacity | 2000 LPH |

| Capacity | 2000 LPH |

| Others: | |

| Recommended Order Quantity | 1 Piece |

| Model Name/Number | MECH O TECH |

| Type | STEAM AND HYDRO DISTILLATION |

| Usage/Application | HYDROSOL, ESSENTIAL OIL DISTILLATION PLANT |

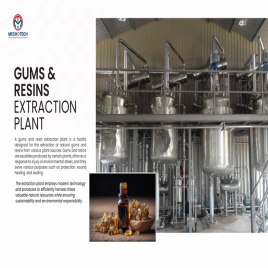

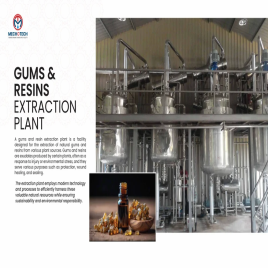

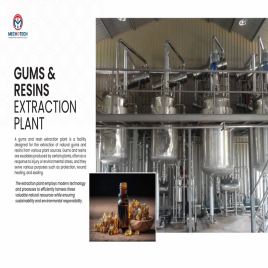

Gums & Resins Distillation Plant, 220 / 415 / 440 V

Brand:

Others

Price ₹

5,00,000.00

| General Details: | |

| Model | Gums & Resins Distillation Plant, 220 / 415 / 440 V |

| Material | SS 304 |

| Capacity | upto 10 tons |

| Voltage | 220 / 415 / 440 V |

| Capacity | upto 10 tons |

| Automation Grade | Semi-Automatic |

| Others: | |

| Brand | MECH O ETCH |

| Country of Origin | Made in India |

| Frequency | 50 / 60 hz |

| Recommended Order Quantity | 1 |

| Usage/Application | Distillation |

GINGER SPICE OIL DISTILLATION PLANT, Capacity: 100 TPD

Brand:

Others

Price ₹

25,00,000.00

| General Details: | |

| Model | GINGER SPICE OIL DISTILLATION PLANT, Capacity: 100 TPD |

| Material | Stainless Steel |

| Capacity | 100 TPD |

| Voltage | 220V |

| Capacity | 100 TPD |

| Automation Grade | Semi-Automatic |

| Others: | |

| Frequency | 50 Hz |

| Power Consumption | 1.5 kW |

| Usage/Application | Used To Extract Perfume And Flavour Oils From Natural Sources. |

Black Pepper Oil Distillation Plant, 220 / 415 V

Brand:

Others

Price ₹

50,00,000.00

| General Details: | |

| Model | Black Pepper Oil Distillation Plant, 220 / 415 V |

| Material | SS 304 |

| Capacity | upto 10 tons |

| Voltage | 220 / 415 V |

| Capacity | upto 10 tons |

| Automation Grade | Semi-Automatic |

| Others: | |

| Brand | MECH O TECH |

| Country of Origin | Made in India |

| Frequency | 50 / 60 HZ |

| Recommended Order Quantity | 1 |

| Usage/Application | Spices Distillation |

Nutmeg Oil Distillation Plant, 220 / 415 / 440 V

Brand:

Others

Price ₹

50,00,000.00

| General Details: | |

| Model | Nutmeg Oil Distillation Plant, 220 / 415 / 440 V |

| Material | SS 304 |

| Capacity | upto 10 tons |

| Voltage | 220 / 415 / 440 v |

| Capacity | upto 10 tons |

| Automation Grade | Semi-Automatic |

| Others: | |

| Brand | MECH O TECH |

| Country of Origin | Made in India |

| Frequency | 50 / 60 HZ |

| Recommended Order Quantity | 1 |

| Usage/Application | Spice Oil Distillation |

SS 304 Aromatic Oils Steam Distillation Plant

Brand:

Others

Price ₹

7,00,000.00

| General Details: | |

| Model | SS 304 Aromatic Oils Steam Distillation Plant |

| Material | SS 304 |

| Capacity | 500 liter |

| Capacity | 500 liter |

| Others: | |

| Brand/Make | MECH O TECH |

| Country of Origin | Made in India |

| Usage/Application | DISTILLATION |

SS 304 HYDRO DISTILLATION UNIT FOR ESSENTIAL OILS, Capacity: 500 liter

Brand:

Others

Price ₹

1,00,000.00

| General Details: | |

| Model | SS 304 HYDRO DISTILLATION UNIT FOR ESSENTIAL OILS, Capacity: 500 liter |

| Material | SS 304 |

| Capacity | 500 liter |

| Capacity | 500 liter |

| Others: | |

| Brand/Make | MECH O TECH |

| Country of Origin | Made in India |

| Usage/Application | STEAM / HYDRO DISTILLATION / HYDROSOL |

SS 304 Hydrosteam Distillation Unit, Capacity: 500 liter

Brand:

Others

Price ₹

1,00,000.00

| General Details: | |

| Model | SS 304 Hydrosteam Distillation Unit, Capacity: 500 liter |

| Material | SS 304 |

| Capacity | 500 liter |

| Capacity | 500 liter |

| Others: | |

| Brand/Make | MECH O TECH |

| Country of Origin | Made in India |

| Usage/Application | DISTILLATION |

Lemongrass Oil Distillation Unit

Brand:

Others

Price ₹

7,00,000.00

| General Details: | |

| Model | Lemongrass Oil Distillation Unit |

| Material | SS 304 |

| Capacity | 500 liter |

| Capacity | 500 liter |

| Others: | |

| Brand/Make | MECH O TECH |

| Country of Origin | Made in India |

| Usage/Application | Steam Distillation |

SS 304 Palmarosa Oil Distilation Plant

Brand:

Others

Price ₹

7,00,000.00

| General Details: | |

| Model | SS 304 Palmarosa Oil Distilation Plant |

| Material | SS 304 |

| Capacity | 500 liter |

| Capacity | 500 liter |

| Others: | |

| Brand/Make | MECH O TECH |

| Country of Origin | Made in India |

| Usage/Application | Distillation |

Ginger Spice Oil Distillation Plant

Brand:

Others

Price ₹

25,00,000.00

| General Details: | |

| Model | GINGER SPICE OIL DISTILLATION PLANT |

| Material | Stainless Steel |

| Capacity | 100 TPD |

| Voltage | 220V |

| Capacity | 100 TPD |

| Automation Grade | Semi-Automatic |

| Others: | |

| Frequency | 50 Hz |

| Power Consumption | 1.5 kW |

| Usage/Application | Used To Extract Perfume And Flavour Oils From Natural Sources. |

Black Pepper Oil Distillation Plant

Brand:

Others

Price ₹

50,00,000.00

| General Details: | |

| Model | Black Pepper Oil Distillation Plant |

| Material | SS 304 |

| Capacity | upto 10 tons |

| Voltage | 220 / 415 V |

| Capacity | upto 10 tons |

| Automation Grade | Semi-Automatic |

| Others: | |

| Brand | MECH O TECH |

| Country of Origin | Made in India |

| Frequency | 50 / 60 HZ |

| Usage/Application | Spices Distillation |

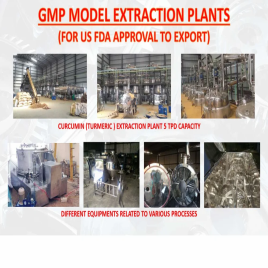

Turmeric Oil Steam Distillation Units

Brand:

Others

Price ₹

7,00,000.00

| General Details: | |

| Model | Turmeric Oil Steam Distillation Units |

| Material | SS |

| Others: | |

| Brand/Make | MECH O TECH |

| Country of Origin | Made in India |

| Model Name/Number | MECH O TECH |

| Usage/Application | TURMERIC STEAM DISTILLATION OIL |

Nutmeg Oil Steam Distillation Plant

Brand:

Others

Price ₹

10,00,000.00

| General Details: | |

| Model | Nutmeg Oil Steam Distillation Plant |

| Material | SS |

| Others: | |

| Brand/Make | MECH O TECH |

| Country of Origin | Made in India |

| Usage/Application | NUT MEG OIL DISTILLATION PLANT |

Small Scale Essential Oil Extraction Machine, For Industrial

Brand:

Others

Price ₹

1,00,000.00

| General Details: | |

| Model | Small Scale Essential Oil Extraction Machine, For Industrial |

| Capacity | 5 ton/day |

| Voltage | 240 V |

| Capacity | 5 ton/day |

| Others: | |

| Frequency | 50 Hz |

| No. of Screws | 50 L |

| Operation Type | Semi Automatic |

| Usage/Application | Industrial |

Ss 304 Hydro Distillation Equipment

Brand:

Others

Price ₹

1,00,000.00

| General Details: | |

| Model | SS 304 HYDRO DISTILLATION EQUIPMENT |

| Material | SS 304 |

| Capacity | 500 liter |

| Capacity | 500 liter |

| Others: | |

| Brand/Make | MECH O TECH |

| Country of Origin | Made in India |

| Usage/Application | DISTILLATION / HYDROSOL |

HYDRO DISTILLATION UNIT, Capacity: 100 L

Brand:

Others

Price ₹

1,00,000.00

| General Details: | |

| Model | HYDRO DISTILLATION UNIT, Capacity: 100 L |

| Capacity | 100 L |

| Capacity | 100 L |

| Others: | |

| Body Material | Stainless Steel |

| Color | Silver |

| Country of Origin | Made in India |

| Pack Type | Box |

| Surface Finish | Polished |

| Usage/Application | Can Be Used |

Ss 304 Aromatic Oil Steam Distillation Unit Manufacturer in India

Brand:

Others

Price ₹

5,00,000.00

| General Details: | |

| Model | SS 304 AROMATIC OIL STEAM DISTILLATION UNIT MANUFACTURER IN INDIA |

| Material | SS 304 |

| Capacity | 500 liter |

| Capacity | 500 liter |

| Others: | |

| Brand/Make | MECH O TECH |

| Country of Origin | Made in India |

| Model Name/Number | MECH O TECH |

| Usage/Application | DISTILLATION |

SS Nagarmotha Oil Steam Distillation Unit, Capacity: 50 liter

Brand:

Others

Price ₹

10,00,000.00

| General Details: | |

| Model | SS Nagarmotha Oil Steam Distillation Unit, Capacity: 50 liter |

| Material | SS |

| Capacity | 50 liter |

| Capacity | 50 liter |

| Others: | |

| Brand/Make | MECH O TECH |

| Country of Origin | Made in India |

| Usage/Application | DISTILLATION |

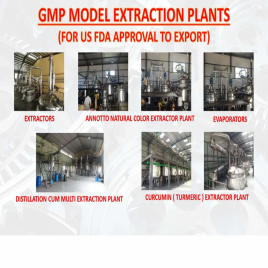

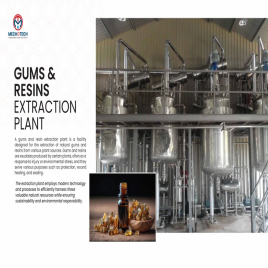

Gums & Resins Distillation Plant

Brand:

Others

Price ₹

5,00,000.00

| General Details: | |

| Model | Gums & Resins Distillation Plant |

| Material | SS 304 |

| Capacity | upto 10 tons |

| Voltage | 220 / 415 / 440 V |

| Capacity | upto 10 tons |

| Automation Grade | Semi-Automatic |

| Others: | |

| Brand | MECH O ETCH |

| Country of Origin | Made in India |

| Frequency | 50 / 60 hz |

| Usage/Application | Distillation |

Turmeric Oil Stream Distillation Plant, Capacity: 50 liter

Brand:

Others

Price ₹

10,00,000.00

| General Details: | |

| Model | Turmeric Oil Stream Distillation Plant, Capacity: 50 liter |

| Material | Yes |

| Capacity | 50 liter |

| Capacity | 50 liter |

| Others: | |

| Brand/Make | Yes |

| Color | Yes |

| Country of Origin | Made in India |

| Model Name/Number | Yes |

| Usage/Application | Yes |

Steam Distillation Plant, Capacity: 50 liter

Brand:

Others

Price ₹

15,00,000.00

| General Details: | |

| Model | Steam Distillation Plant, Capacity: 50 liter |

| Material | Yes |

| Capacity | 50 liter |

| Capacity | 50 liter |

| Others: | |

| Brand/Make | Yes |

| Country of Origin | Made in India |

| Model Name/Number | Yes |

| Usage/Application | Yes |

Stainless Steel 1 ton field level distillation plant, Capacity: 50 liter

Brand:

Others

Price ₹

15,00,000.00

| General Details: | |

| Model | Stainless Steel 1 ton field level distillation plant, Capacity: 50 liter |

| Material | Yes |

| Capacity | 50 liter |

| Capacity | 50 liter |

| Others: | |

| Brand/Make | Yes |

| Country of Origin | Made in India |

| Model Name/Number | Yes |

| Usage/Application | Yes |

Myrrh distillation plant, Capacity: 10 L

Brand:

Others

Price ₹

15,00,000.00

| General Details: | |

| Model | Myrrh distillation plant, Capacity: 10 L |

| Capacity | 10 L |

| Capacity | 10 L |

| Others: | |

| Chloride | Yes |

| Filtered Through | Yes |

| Inlet Flow Rate | Yes |

| Motor Power | Yes |

| Nitrite | Yes |

| Silica | Yes |

| Size | Yes |

| Usage/Application | Yes |

Nutmeg Oil Distillation Plant

Brand:

Others

Price ₹

50,00,000.00

| General Details: | |

| Model | Nutmeg Oil Distillation Plant |

| Material | SS 304 |

| Capacity | upto 10 tons |

| Voltage | 220 / 415 / 440 v |

| Capacity | upto 10 tons |

| Automation Grade | Semi-Automatic |

| Others: | |

| Brand | MECH O TECH |

| Country of Origin | Made in India |

| Frequency | 50 / 60 HZ |

| Usage/Application | Spice Oil Distillation |

100 lit Steam Distillation Plant, Capacity: 50 liter

Brand:

Others

Price ₹

10,00,000.00

| General Details: | |

| Model | 100 lit Steam Distillation Plant, Capacity: 50 liter |

| Material | Yes |

| Capacity | 50 liter |

| Capacity | 50 liter |

| Others: | |

| Brand/Make | Yes |

| Country of Origin | Made in India |

| Model Name/Number | Yes |

| Usage/Application | Yes |

Lab model Distillation Plant

Brand:

Others

Price ₹

10,00,000.00

| General Details: | |

| Model | Lab model Distillation Plant |

| Material | Yes |

| Capacity | upto 10 tons |

| Capacity | upto 10 tons |

| Automation Grade | Semi-Automatic |

| Others: | |

| Brand | Yes |

| Country of Origin | Made in India |

| Frequency | Yes |

| Usage/Application | Yes |

SS 304 Steam Cum Hydrodistillation Unit, Capacity: 500 liter

Brand:

Others

Price ₹

1,23,000.00

| General Details: | |

| Model | SS 304 Steam Cum Hydrodistillation Unit, Capacity: 500 liter |

| Material | SS 304 |

| Capacity | 500 liter |

| Capacity | 500 liter |

| Others: | |

| Brand/Make | MECH O TECH |

| Country of Origin | Made in India |

| Usage/Application | STEAM DISTILLATION / HYDRO DISTILLATION / HYDROSOL |

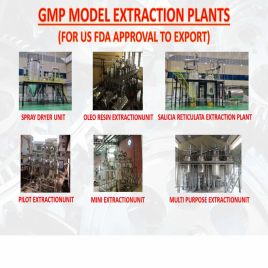

Steam distillation unit for essential oils

Brand:

Others

Price ₹

1,00,00,000.00

| General Details: | |

| Model | Steam distillation unit for essential oils |

| Others: | |

| Brand/Make | MECH O TECH |

| Material | SS |

| Minimum Order Quantity | 1 |

| Model | SS Nagarmotha Oil Steam Distillation Unit |

| Usage/Application | DISTILLATION |

Essential oil distillation kit

Brand:

Others

Price ₹

7,00,000.00

| General Details: | |

| Model | Essential oil distillation kit |

| Others: | |

| Brand/Make | MECH O TECH |

| Material | SS |

| Model Name/Number | MECH O TECH |

| Model | Turmeric Oil Steam Distillation Units |

| Usage/Application | TURMERIC STEAM DISTILLATION OIL |

Cardamom Oil Distillation Plant

Brand:

Others

Price ₹

10,00,000.00

| General Details: | |

| Model | Essential oil manufacturing machine |

| Material | Stainless Steel |

| Capacity | Semi Automatic |

| Applications | 415 |

| Power Source | Electrical |

| Voltage | yes |

| Usage | Customization |

| Capacity | Essential OIl |

| Design Type | Yes |

| Automation Grade | Electrical |

| Operation Mode | Yes |

| Surface | Yes |

| Finishing | Yes |

| Supplied with | Yes |

| Electric supply | Yes |

if you are interested, please fill the below details: