Oil Distillation Plant

Multi Aromatic Oil Distillation Plant, Capacity: 500 TPD

Brand:

Others

Price ₹

1,00,00,000.00

| General Details: | |

| Model | Multi Aromatic Oil Distillation Plant, Capacity: 500 TPD |

| Material | Stainless Steel |

| Automation Grade | Semi-Automatic |

| Frequency | 50 Hz |

| Voltage | 230V |

| Usage/Application | For Essential Oil From Aromatic Plants |

| Others: | |

| Capacity | 500 TPD |

| Power Consumption | 1 HP |

Mint Oil Distillation Unit, Capacity: 10 TPD

Brand:

Others

Price ₹

1,25,00,000.00

| General Details: | |

| Model | Mint Oil Distillation Unit, Capacity: 10 TPD |

| Automation Grade | Semi Automatic |

| Frequency | 50 / 60 HZ |

| Voltage | 220 / 415 / 440 V |

| Usage/Application | Oil Distillation |

| Others: | |

| Capacity | 10 TPD |

| Country of Origin | Made in India |

| Recommended Order Quantity | 1 |

Small Scale Essential Oil Distillation Plant, Capacity: 50 TPD

Brand:

Others

Price ₹

1,75,00,000.00

| General Details: | |

| Model | Small Scale Essential Oil Distillation Plant, Capacity: 50 TPD |

| Automation Grade | Semi Automatic |

| Frequency | 50 Hz |

| Power Source | Electric |

| Voltage | 220 V |

| Usage/Application | Industrial |

| Others: | |

| Capacity | 50 TPD |

Aromatic Essential Oil Distillation Plants, Capacity: 100 TPD

Brand:

Others

Price ₹

1,11,75,000.00

| General Details: | |

| Model | Aromatic Essential Oil Distillation Plants, Capacity: 100 TPD |

| Automation Grade | Semi Automatic |

| Frequency | 50 / 60 HZ |

| Power Source | WOOD |

| Usage/Application | DISTILLATION |

| Others: | |

| Capacity | 100 TPD |

| Country of Origin | Made in India |

| Recommended Order Quantity | 1 |

| Power Consumption | ELECTRICAL |

Small Scale Aromatic Oil Distillation Equipment, Capacity: 50 TPD

Brand:

Others

Price ₹

1,24,58,000.00

| General Details: | |

| Automation Grade | Semi Automatic |

| Frequency | 50 Hz |

| Power Source | Electric |

| Voltage | 220 V |

| Usage/Application | Industrial |

| Others: | |

| Capacity | 50 TPD |

Rose Oil Distillation Plant, Capacity: 10 TPD

Brand:

Others

Price ₹

78,000.00

| General Details: | |

| Model | Rose Oil Distillation Plant, Capacity: 10 TPD |

| Automation Grade | Semi Automatic |

| Frequency | 50 / 60 HZ |

| Power Source | LPG GAS |

| Usage/Application | DISTILLATION |

| Others: | |

| Capacity | 10 TPD |

| Country of Origin | Made in India |

| Recommended Order Quantity | 1 |

Mini Essential Oil Distillation Plant, Capacity: 50 TPD

Brand:

Others

Price ₹

1,21,75,000.00

| General Details: | |

| Model | Mini Essential Oil Distillation Plant, Capacity: 50 TPD |

| Automation Grade | Semi Automatic |

| Frequency | 50 Hz |

| Power Source | Electric |

| Voltage | 220 V |

| Usage/Application | Industrial |

| Others: | |

| Capacity | 50 TPD |

Rose Hydrosol Distillation Plant, Capacity: 10 TPD

Brand:

Others

Price ₹

1,00,50,000.00

| General Details: | |

| Model | Rose Hydrosol Distillation Plant, Capacity: 10 TPD |

| Automation Grade | Semi Automatic |

| Frequency | 50 / 60 HZ |

| Power Source | LPG GAS |

| Usage/Application | HYDROSOL |

| Others: | |

| Capacity | 10 TPD |

| Country of Origin | Made in India |

| Recommended Order Quantity | 1 |

| Power Consumption | LPG GAS |

Oil Distillation Plant Manufacturers In India, Capacity: 100 TPD

Brand:

Others

Price ₹

1,03,00,000.00

| General Details: | |

| Model | Oil Distillation Plant Manufacturers In India, Capacity: 100 TPD |

| Automation Grade | Semi Automatic |

| Power Source | Electrical |

| Voltage | 415 |

| Usage/Application | Distillation |

| Others: | |

| Capacity | 100 TPD |

| Country of Origin | Made in India |

| Recommended Order Quantity | 1 |

Curry Leaves Distillation Plant, Capacity: 5 TPD

Brand:

Others

Price ₹

1,01,50,000.00

| General Details: | |

| Model | Curry Leaves Distillation Plant, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | 50 / 60 HZ |

| Design | Customized |

| Usage/Application | DISTILLATION / HYDROSOL |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Recommended Order Quantity | 1 |

Aromatic Oil Distillation Plant Manufacturer In India, Capacity: 100 TPD

Brand:

Others

Price ₹

1,07,00,000.00

| General Details: | |

| Model | Aromatic Oil Distillation Plant Manufacturer In India, Capacity: 100 TPD |

| Automation Grade | Semi Automatic |

| Frequency | 50 / 60 HZ |

| Power Source | ELECTRICAL AND WOOD |

| Voltage | 415 |

| Others: | |

| Capacity | 100 TPD |

| Country of Origin | Made in India |

| Recommended Order Quantity | 1 |

Tulsi Oil Distillation Plant, Capacity: 10 TPD

Brand:

Others

Price ₹

1,30,20,000.00

| General Details: | |

| Model | Tulsi Oil Distillation Plant, Capacity: 10 TPD |

| Automation Grade | Semi Automatic |

| Frequency | 50 HZ |

| Power Source | ELECTRICAL |

| Voltage | 220 V |

| Usage/Application | TULSI OIL DISTILLATION PLANT |

| Others: | |

| Capacity | 10 TPD |

| Country of Origin | Made in India |

| Recommended Order Quantity | 1 |

Essential Oil Field Distillation Unit, Capacity: 500 TPD

Brand:

Others

Price ₹

1,07,00,000.00

| General Details: | |

| Model | Essential Oil Field Distillation Unit, Capacity: 500 TPD |

| Automation Grade | Semi Automatic |

| Frequency | 50 HZ |

| Voltage | 415 |

| Usage/Application | DISTILLATION PLANT |

| Others: | |

| Capacity | 500 TPD |

| Country of Origin | Made in India |

| Recommended Order Quantity | 1 |

Essential Oil Distillation Unit, Capacity: 5 TPD

Brand:

Others

Price ₹

1,70,00,000.00

| General Details: | |

| Model | Essential Oil Distillation Unit, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | 50 HZ |

| Power Source | WOOD / GRASS / ELECTRICAL |

| Voltage | 220 / 415 V |

| Usage/Application | STEAM DISTILLATION |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Recommended Order Quantity | 1 |

Automatic Essential Oil Distillation Plant, Capacity: 5 TPD

Brand:

Others

Price ₹

1,70,00,000.00

| General Details: | |

| Model | Automatic Essential Oil Distillation Plant, Capacity: 5 TPD |

| Automation Grade | Automatic |

| Frequency | 50 HZ |

| Power Source | WOOD |

| Voltage | 220 / 415 V |

| Usage/Application | STEAM DISTILLATION |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Recommended Order Quantity | 1 |

Essential Oil Distillation, Capacity: 500 TPD

Brand:

Others

Price ₹

1,54,80,000.00

| General Details: | |

| Model | Essential Oil Distillation, Capacity: 500 TPD |

| Automation Grade | Semi Automatic |

| Frequency | 50 HZ |

| Voltage | 415 V |

| Usage/Application | DISTILLATION |

| Others: | |

| Capacity | 500 TPD |

| Country of Origin | Made in India |

| Recommended Order Quantity | 1 |

Small Scale Essential Oil Distillation Unit

Brand:

Others

Price ₹

1,00,00,000.00

| General Details: | |

| Model | Small Scale Essential Oil Distillation Unit |

| Automation Grade | Semi Automatic |

| Frequency | 50 HZ |

| Power Source | GAS / ELECTRICAL |

| Voltage | 220 / 415 V |

| Usage/Application | STEAM / HYDRO DISTILLATION |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Recommended Order Quantity | 1 |

Essential Oil Distillation Machine, Capacity: 5 TPD

Brand:

Others

Price ₹

1,68,00,000.00

| General Details: | |

| Model | Essential Oil Distillation Machine, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | 50 HZ |

| Power Source | FIRE WOOD / ELECTRIACL |

| Voltage | 220 / 415 V |

| Usage/Application | STEAM DISTILLATION |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Recommended Order Quantity | 1 |

Essential Oil Distillation Plant Manufacturers In India, Capacity: 100 TPD

Brand:

Others

Price ₹

1,30,00,000.00

| General Details: | |

| Model | Essential Oil Distillation Plant Manufacturers In India, Capacity: 100 TPD |

| Automation Grade | Semi Automatic |

| Frequency | 50 / 60 HZ |

| Voltage | 220 / 415 V |

| Usage/Application | DISTILLATION |

| Others: | |

| Capacity | 100 TPD |

| Country of Origin | Made in India |

| Recommended Order Quantity | 1 |

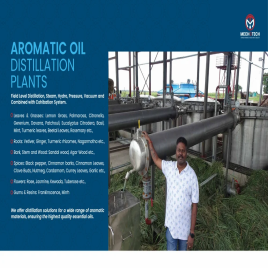

Aromatic Oil Distillation Plant, Capacity: 100 TPD

Brand:

Others

Price ₹

1,16,87,000.00

| General Details: | |

| Model | Aromatic Oil Distillation Plant, Capacity: 100 TPD |

| Automation Grade | Semi Automatic |

| Frequency | 50 HZ |

| Power Source | WOOD, DIESEL, GAS, ELECTRICITY |

| Voltage | 220 / 415 V |

| Usage/Application | STEAM DISTILLATION PLANT |

| Others: | |

| Capacity | 100 TPD |

| Country of Origin | Made in India |

| Recommended Order Quantity | 1 |

Sandal Wood Distillation Plant, 415

Brand:

Others

Price ₹

1,50,00,000.00

| General Details: | |

| Model | Sandal Wood Distillation Plant, 415 |

| Material | ss |

| Automation Grade | Semi-Automatic |

| Frequency | 50 |

| Voltage | 415 |

| Others: | |

| Brand | MECH O TECH |

| Capacity | upto 10 tons |

| Country of Origin | Made in India |

| Recommended Order Quantity | 1 |

SS Nagarmotha Oil Steam Distillation Unit

Brand:

Others

Price ₹

1,00,00,000.00

| General Details: | |

| Model | SS Nagarmotha Oil Steam Distillation Unit |

| Material | SS |

| Usage/Application | DISTILLATION |

| Others: | |

| Brand/Make | MECH O TECH |

| Country of Origin | Made in India |

| Recommended Order Quantity | 1 |

Vetiver Essential Oil Distillation Unit, Capacity: 50 TPD

Brand:

Others

Price ₹

1,25,00,000.00

| General Details: | |

| Model | Vetiver Essential Oil Distillation Unit, Capacity: 50 TPD |

| Automation Grade | Semi Automatic |

| Frequency | 50 Hz |

| Voltage | 220V |

| Usage/Application | Vetiver Essential Oil Steam Distillation Plant |

| Others: | |

| Capacity | 50 TPD |

| Country of Origin | Made in India |

| Recommended Order Quantity | 1 |

Citronella Oil Distillation Plant, Capacity: 100 TPD

Brand:

Others

Price ₹

1,35,00,000.00

| General Details: | |

| Model | Citronella Oil Distillation Plant, Capacity: 100 TPD |

| Automation Grade | Semi Automatic |

| Frequency | 50 Hz |

| Power Source | Electrical |

| Voltage | 220V |

| Usage/Application | Citronella Oil Distillation Plant |

| Others: | |

| Capacity | 100 TPD |

| Country of Origin | Made in India |

| Recommended Order Quantity | 1 |

Geranium Oil Distillation Plant, Capacity: 100 TPD

Brand:

Others

Price ₹

1,44,79,500.00

| General Details: | |

| Model | Geranium Oil Distillation Plant, Capacity: 100 TPD |

| Automation Grade | Semi Automatic |

| Frequency | 50 Hz |

| Power Source | Electrical / Wood |

| Usage/Application | Distillation |

| Others: | |

| Capacity | 100 TPD |

| Country of Origin | Made in India |

| Recommended Order Quantity | 1 |

Field Distillation Unit For Essential Oil, Capacity: 500 TPD

Brand:

Others

Price ₹

1,60,00,000.00

| General Details: | |

| Model | Field Distillation Unit For Essential Oil, Capacity: 500 TPD |

| Automation Grade | Semi Automatic |

| Voltage | 415 |

| Others: | |

| Capacity | 500 TPD |

| Country of Origin | Made in India |

| Recommended Order Quantity | 1 |

Small Essential Oil Distillation, Capacity: 5 TPD

Brand:

Others

Price ₹

1,33,65,000.00

| General Details: | |

| Model | Small Essential Oil Distillation, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | 50 HZ |

| Power Source | GAS / ELECTRICAL |

| Voltage | 220 / 415 V |

| Usage/Application | STEAM / HYDRO DISTILLATION |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Recommended Order Quantity | 1 |

Mini Aromatic Oil Distillation Equipment, Capacity: 50 TPD

Brand:

Others

Price ₹

1,75,00,000.00

| General Details: | |

| Model | Mini Aromatic Oil Distillation Equipment, Capacity: 50 TPD |

| Automation Grade | Semi Automatic |

| Frequency | 60 Hz |

| Power Source | Electric |

| Voltage | 220 V |

| Usage/Application | Industrial |

| Others: | |

| Capacity | 50 TPD |

Sandal Wood Oil Distillation Plant, Capacity: 5 TPD

Brand:

Others

Price ₹

1,00,50,000.00

| General Details: | |

| Model | Sandal Wood Oil Distillation Plant, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | 50 / 60 HZ |

| Power Source | Steam |

| Voltage | 415V |

| Usage/Application | Sandal Wood Oil Distillation Plant |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Recommended Order Quantity | 1 |

Essential Oil Distillation Plant, Capacity: 5 TPD

Brand:

Others

Price ₹

1,00,00,000.00

| General Details: | |

| Model | Essential Oil Distillation Plant, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | 50 HZ |

| Power Source | ELECTRICAL |

| Voltage | 415 |

| Usage/Application | PILOT TYPE DISTILLATION UNIT |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Recommended Order Quantity | 1 |

Agar Wood Oil Distillation Plant, Capacity: 5 TPD

Brand:

Others

Price ₹

1,00,00,000.00

| General Details: | |

| Model | Agar Wood Oil Distillation Plant, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | 50 / 60 hz |

| Power Source | Gas fired |

| Voltage | 415 |

| Usage/Application | Agar wood oil Distillation Plant |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Recommended Order Quantity | 1 |

Lemon Grass Essential Oil Distillation Plant, Capacity: 50 TPD

Brand:

Others

Price ₹

1,07,00,000.00

| General Details: | |

| Model | Lemon Grass Essential Oil Distillation Plant, Capacity: 50 TPD |

| Automation Grade | Semi Automatic |

| Frequency | 50 / 60 HZ |

| Power Source | Electrical |

| Voltage | 415 |

| Usage/Application | Aromatic Oil Distillation Plant |

| Others: | |

| Capacity | 50 TPD |

| Country of Origin | Made in India |

| Recommended Order Quantity | 1 |

Cinnamon Bark Oil Distillation Plant, Capacity: 10 TPD

Brand:

Others

Price ₹

5,00,00,000.00

| General Details: | |

| Model | Cinnamon Bark Oil Distillation Plant, Capacity: 10 TPD |

| Automation Grade | Semi Automatic |

| Frequency | 50 / 60 hz |

| Voltage | 220 / 415 / 440 V |

| Usage/Application | Spice Oil Distillation |

| Others: | |

| Capacity | 10 TPD |

| Country of Origin | Made in India |

| Recommended Order Quantity | 1 |

Cinnamon Leaf Oil Distillation Plant, Capacity: 5 TPD

Brand:

Others

Price ₹

1,50,00,000.00

| General Details: | |

| Model | Cinnamon Leaf Oil Distillation Plant, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | 50 / 60 hz |

| Voltage | 220 / 415 / 440 V |

| Usage/Application | Spice Oil Distillation |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Recommended Order Quantity | 1 |

Turmeric Oil Distillation Plant, Capacity: 5 TPD

Brand:

Others

Price ₹

2,50,00,000.00

| General Details: | |

| Model | Turmeric Oil Distillation Plant, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | 50 / 60 hz |

| Voltage | 220 / 415 / 440 V |

| Usage/Application | Essential Oil Distillation |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Recommended Order Quantity | 1 |

Ginger Oil Distillation Plant, Capacity: 5 TPD

Brand:

Others

Price ₹

1,30,00,000.00

| General Details: | |

| Model | Ginger Oil Distillation Plant, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | 50 / 60 HZ |

| Voltage | 220 / 415 /440 V |

| Usage/Application | Oil Distillation |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Recommended Order Quantity | 1 |

Spice Oil Distillation Plant, Capacity: 10 TPD

Brand:

Others

Price ₹

1,50,00,000.00

| General Details: | |

| Model | Spice Oil Distillation Plant, Capacity: 10 TPD |

| Automation Grade | Semi Automatic |

| Frequency | 50 / 60 hz |

| Power Source | Electrical |

| Voltage | 220 / 415 volts |

| Usage/Application | Spice oil distillation |

| Others: | |

| Capacity | 10 TPD |

| Country of Origin | Made in India |

| Recommended Order Quantity | 1 |

Spice Distillation Plant, Capacity: 10 TPD

Brand:

Others

Price ₹

1,05,00,000.00

| General Details: | |

| Model | Spice Distillation Plant, Capacity: 10 TPD |

| Automation Grade | Semi Automatic |

| Frequency | 50 / 60 HZ |

| Power Source | ELECTRICAL |

| Voltage | 220 / 415 V |

| Usage/Application | SPICE OIL DISTILLATION |

| Others: | |

| Capacity | 10 TPD |

| Country of Origin | Made in India |

| Recommended Order Quantity | 1 |

SS Turmeric Oil Steam Distillation Units

Brand:

Others

Price ₹

1,07,00,000.00

| General Details: | |

| Model | SS Turmeric Oil Steam Distillation Units |

| Material | SS |

| Usage/Application | TURMERIC STEAM DISTILLATION OIL |

| Others: | |

| Brand/Make | MECH O TECH |

| Country of Origin | Made in India |

| Recommended Order Quantity | 1 |

| Model Name/Number | MECH O TECH |

Turmeric Leaf Oil Distillation Plant, Capacity: 10 TPD

Brand:

Others

Price ₹

1,25,00,000.00

| General Details: | |

| Model | Turmeric Leaf Oil Distillation Plant, Capacity: 10 TPD |

| Automation Grade | Semi Automatic |

| Frequency | 50 / 60 hz |

| Voltage | 220 / 415 / 440 V |

| Usage/Application | Turmeric Oil Distillation |

| Others: | |

| Capacity | 10 TPD |

| Country of Origin | Made in India |

| Recommended Order Quantity | 1 |

Black Pepper Spice Oil Distillation Plant, Capacity: 5 TPD

Brand:

Others

Price ₹

1,00,00,000.00

| General Details: | |

| Model | Black Pepper Spice Oil Distillation Plant, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | 60Hz |

| Power Source | Electrical / Steam |

| Voltage | 415V |

| Usage/Application | Black Pepper Distillation Plant |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Recommended Order Quantity | 1 |

Cinnamon Spice Oil Distillation Plant

Brand:

Others

Price ₹

1,05,00,000.00

| General Details: | |

| Model | Cinnamon Spice Oil Distillation Plant |

| Material | Stainless Steel |

| Automation Grade | Automatic |

| Frequency | 50 Hz |

| Voltage | 220V |

| Usage/Application | Used For Oil Refining, Water Purification, And The Creation Of Alcoholic Beverages. |

| Others: | |

| Capacity | 50 tons |

| Power Consumption | 1.5 kW |

SS Nutmeg Oil Steam Distillation Plant

Brand:

Others

Price ₹

1,50,00,000.00

| General Details: | |

| Model | SS Nutmeg Oil Steam Distillation Plant |

| Material | SS |

| Usage/Application | NUT MEG OIL DISTILLATION PLANT |

| Others: | |

| Brand/Make | MECH O TECH |

| Country of Origin | Made in India |

| Recommended Order Quantity | 1 |

Turmeric Leaf Oil Distillation Plant, Capacity: 5 TPD

Brand:

Others

Price ₹

1,07,50,000.00

| General Details: | |

| Model | Turmeric Leaf Oil Distillation Plant, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | 50 Hz |

| Power Source | Electrical And Wood |

| Voltage | Single Phase |

| Usage/Application | Turmeric Leaf Oil Steam Distillation Unit |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Recommended Order Quantity | 1 |

Clove Leaf Oil Distillation Plant, Capacity: 5 TPD

Brand:

Others

Price ₹

1,00,00,000.00

| General Details: | |

| Model | Clove Leaf Oil Distillation Plant, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | 50Hz |

| Power Source | Electrical And Wood |

| Voltage | 415V |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Recommended Order Quantity | 1 |

Frankincense Oil Steam Distillation Plant, Capacity: 5 TPD

Brand:

Others

Price ₹

1,50,00,000.00

| General Details: | |

| Model | Frankincense Oil Steam Distillation Plant, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | 50 / 60 HZ |

| Voltage | 220 / 415 / 440 V |

| Usage/Application | Frankincense Oil Distillation |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Recommended Order Quantity | 1 |

Myrrh Oil Distillation Plant, Capacity: 5 TPD

Brand:

Others

Price ₹

1,05,00,000.00

| General Details: | |

| Model | Myrrh Oil Distillation Plant, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | 50 / 60 HZ |

| Voltage | 220 / 415 / 440 V |

| Usage/Application | Myrrh Distillation |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Recommended Order Quantity | 1 |

Multi Aromatic Oil Distillation Plant

Brand:

Others

Price ₹

1,00,00,000.00

| General Details: | |

| Model | Multi Aromatic Oil Distillation Plant |

| Material | Stainless Steel |

| Automation Grade | Semi-Automatic |

| Frequency | 50 Hz |

| Voltage | 230V |

| Usage/Application | For Essential Oil From Aromatic Plants |

| Others: | |

| Capacity | 500 TPD |

| Power Consumption | 1 HP |

Xanthoxylum /Timur (Leaves / Berries) Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

5,00,000.00

| General Details: | |

| Model | Xanthoxylum /Timur (Leaves / Berries) Oils Distillation Plants, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | yes |

| Power Source | yes |

| Voltage | yes |

| Usage/Application | yes |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | yes |

Yarrow (Leaves / Flowers / Buds) Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

8,00,000.00

| General Details: | |

| Model | Yarrow (Leaves / Flowers / Buds) Oils Distillation Plants, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | yes |

| Power Source | yes |

| Voltage | yes |

| Usage/Application | yes |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | yes |

Rosalina / Ericifolia (Leaves) Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

10,00,000.00

| General Details: | |

| Model | Rosalina / Ericifolia (Leaves) Oils Distillation Plants, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | yes |

| Power Source | yes |

| Voltage | yes |

| Usage/Application | yes |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | yes |

Rose Geranium (Leaves) Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

7,50,000.00

| General Details: | |

| Model | Rose Geranium (Leaves) Oils Distillation Plants, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | yes |

| Power Source | yes |

| Voltage | yes |

| Usage/Application | yes |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | yes |

Rosemary (Leaves / Flowers / Buds) Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

8,50,000.00

| General Details: | |

| Model | Rosemary (Leaves / Flowers / Buds) Oils Distillation Plants, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | yes |

| Power Source | yes |

| Voltage | yes |

| Usage/Application | yes |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | yes |

Peppermint (Leaves / Flowers / Buds) Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

7,50,000.00

| General Details: | |

| Model | Peppermint (Leaves / Flowers / Buds) Oils Distillation Plants, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | yes |

| Power Source | yes |

| Voltage | yes |

| Usage/Application | yes |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | yes |

Palmrosa (Grass) Leaves Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

7,80,000.00

| General Details: | |

| Model | Palmrosa (Grass) Leaves Oils Distillation Plants, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | yes |

| Power Source | yes |

| Voltage | yes |

| Usage/Application | yes |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | yes |

Patchouli (Leaves) Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

8,60,000.00

| General Details: | |

| Model | Patchouli (Leaves) Oils Distillation Plants, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | yes |

| Power Source | yes |

| Voltage | yes |

| Usage/Application | yes |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | yes |

Saro (Leaves) Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

10,00,000.00

| General Details: | |

| Model | Saro (Leaves) Oils Distillation Plants, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | yes |

| Power Source | yes |

| Voltage | yes |

| Usage/Application | yes |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | yes |

Spearmint (Leaves / Flowers / Buds) Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

15,00,000.00

| General Details: | |

| Model | Spearmint (Leaves / Flowers / Buds) Oils Distillation Plants, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | yes |

| Power Source | yes |

| Voltage | yes |

| Usage/Application | yes |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | yes |

Thyme (Leaves / Flowers / Buds) Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

7,60,000.00

/ Metric Ton

| General Details: | |

| Model | Thyme (Leaves / Flowers / Buds) Oils Distillation Plants, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | yes |

| Power Source | yes |

| Voltage | yes |

| Usage/Application | yes |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | yes |

Turmeric (Leaves) Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

6,50,000.00

| General Details: | |

| Model | Turmeric (Leaves) Oils Distillation Plants, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | yes |

| Power Source | yes |

| Voltage | yes |

| Usage/Application | yes |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | yes |

WinterGreen (Leaves) Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

20,00,000.00

| General Details: | |

| Model | WinterGreen (Leaves) Oils Distillation Plants, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | yes |

| Power Source | yes |

| Voltage | yes |

| Usage/Application | yes |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | yes |

Rhododendron Ledum (Flowers / Leaves) Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

15,00,000.00

| General Details: | |

| Model | Rhododendron Ledum (Flowers / Leaves) Oils Distillation Plants, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | yes |

| Power Source | yes |

| Voltage | yes |

| Usage/Application | yes |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | yes |

Ravensara (Leaves) Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

10,00,000.00

| General Details: | |

| Model | Ravensara (Leaves) Oils Distillation Plants, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | yes |

| Power Source | yes |

| Voltage | yes |

| Usage/Application | yes |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | yes |

Ravintsara (Leaves) Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

7,90,000.00

| General Details: | |

| Model | Ravintsara (Leaves) Oils Distillation Plants, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | yes |

| Power Source | yes |

| Voltage | yes |

| Usage/Application | yes |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | yes |

Myrtle (Leaves) Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

7,50,000.00

| General Details: | |

| Model | Myrtle (Leaves) Oils Distillation Plants, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | yes |

| Power Source | yes |

| Voltage | yes |

| Usage/Application | yes |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | yes |

Niaouli (Leaves) Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

10,00,000.00

| General Details: | |

| Model | Niaouli (Leaves) Oils Distillation Plants, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | yes |

| Power Source | yes |

| Voltage | yes |

| Usage/Application | yes |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | yes |

Ocotea (Leaves) Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

7,50,000.00

| General Details: | |

| Model | Ocotea (Leaves) Oils Distillation Plants, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | yes |

| Power Source | yes |

| Voltage | yes |

| Usage/Application | yes |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | yes |

Oregano (Leaves / Flowers / Buds) Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

15,00,000.00

| General Details: | |

| Model | Oregano (Leaves / Flowers / Buds) Oils Distillation Plants, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | yes |

| Power Source | yes |

| Voltage | yes |

| Usage/Application | yes |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | yes |

Lemon Eucalyptus (Leaves) Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

17,50,000.00

| General Details: | |

| Model | Lemon Eucalyptus (Leaves) Oils Distillation Plants, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | yes |

| Power Source | yes |

| Voltage | yes |

| Usage/Application | yes |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | yes |

Lemon (Grass) Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

8,50,000.00

| General Details: | |

| Model | Lemon (Grass) Oils Distillation Plants, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | yes |

| Power Source | yes |

| Voltage | yes |

| Usage/Application | yes |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | yes |

Lemon Verbena (Leaves) Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

9,50,000.00

| General Details: | |

| Model | Lemon Verbena (Leaves) Oils Distillation Plants, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | yes |

| Power Source | yes |

| Voltage | yes |

| Usage/Application | yes |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | yes |

Marjoram (Leaves / Flowers / Buds) Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

10,00,000.00

| General Details: | |

| Model | Marjoram (Leaves / Flowers / Buds) Oils Distillation Plants, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | yes |

| Power Source | yes |

| Voltage | yes |

| Usage/Application | yes |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | yes |

May Chang (Fruit) Leaves Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

8,00,000.00

| General Details: | |

| Model | May Chang (Fruit) Leaves Oils Distillation Plants, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | yes |

| Power Source | yes |

| Voltage | yes |

| Usage/Application | yes |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | yes |

Kunzea (Leaves) Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

15,00,000.00

| General Details: | |

| Model | Kunzea (Leaves) Oils Distillation Plants, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | yes |

| Power Source | yes |

| Voltage | yes |

| Usage/Application | yes |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | yes |

Holy Basil Leaves Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

8,00,000.00

| General Details: | |

| Model | Holy Basil Leaves Oils Distillation Plants, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | yes |

| Power Source | yes |

| Voltage | yes |

| Usage/Application | yes |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | yes |

Hops (Flowers / Cones) Leaves Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

10,00,000.00

| General Details: | |

| Model | Hops (Flowers / Cones) Leaves Oils Distillation Plants, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | yes |

| Power Source | yes |

| Voltage | yes |

| Usage/Application | yes |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | yes |

Hyssop (Leaves / Flowers / Buds)Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

8,00,000.00

| General Details: | |

| Model | Hyssop (Leaves / Flowers / Buds)Oils Distillation Plants, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | yes |

| Power Source | yes |

| Voltage | yes |

| Usage/Application | yes |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | yes |

Kaffir Lime Petitgrain (Leaves & Twigs) Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

15,00,000.00

| General Details: | |

| Model | Kaffir Lime Petitgrain (Leaves & Twigs) Oils Distillation Plants, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | yes |

| Power Source | yes |

| Voltage | yes |

| Usage/Application | yes |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | yes |

Kanuka / Manuka / Teatree (Leaves) Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

16,00,000.00

| General Details: | |

| Model | Kanuka / Manuka / Teatree (Leaves) Oils Distillation Plants, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | yes |

| Power Source | yes |

| Voltage | yes |

| Usage/Application | yes |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | yes |

Eucalyptus Globolus Leaves Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

75,00,000.00

| General Details: | |

| Model | Eucalyptus Globolus Leaves Oils Distillation Plants, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | yes |

| Power Source | yes |

| Voltage | yes |

| Usage/Application | yes |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | yes |

Eucalyptus Radiata Leaves Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

9,60,000.00

| General Details: | |

| Model | Eucalyptus Radiata Leaves Oils Distillation Plants, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | yes |

| Power Source | yes |

| Voltage | yes |

| Usage/Application | yes |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | yes |

Fragonia Leaves Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

10,00,000.00

| General Details: | |

| Model | Fragonia Leaves Oils Distillation Plants, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | yes |

| Power Source | yes |

| Voltage | yes |

| Usage/Application | yes |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | yes |

Geranium Leaves Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

9,70,000.00

| General Details: | |

| Model | Geranium Leaves Oils Distillation Plants, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | yes |

| Power Source | yes |

| Voltage | yes |

| Usage/Application | yes |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | yes |

Corn Mint Leaves Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

25,00,000.00

| General Details: | |

| Model | Corn Mint Leaves Oils Distillation Plants, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | yes |

| Power Source | yes |

| Voltage | yes |

| Usage/Application | yes |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | yes |

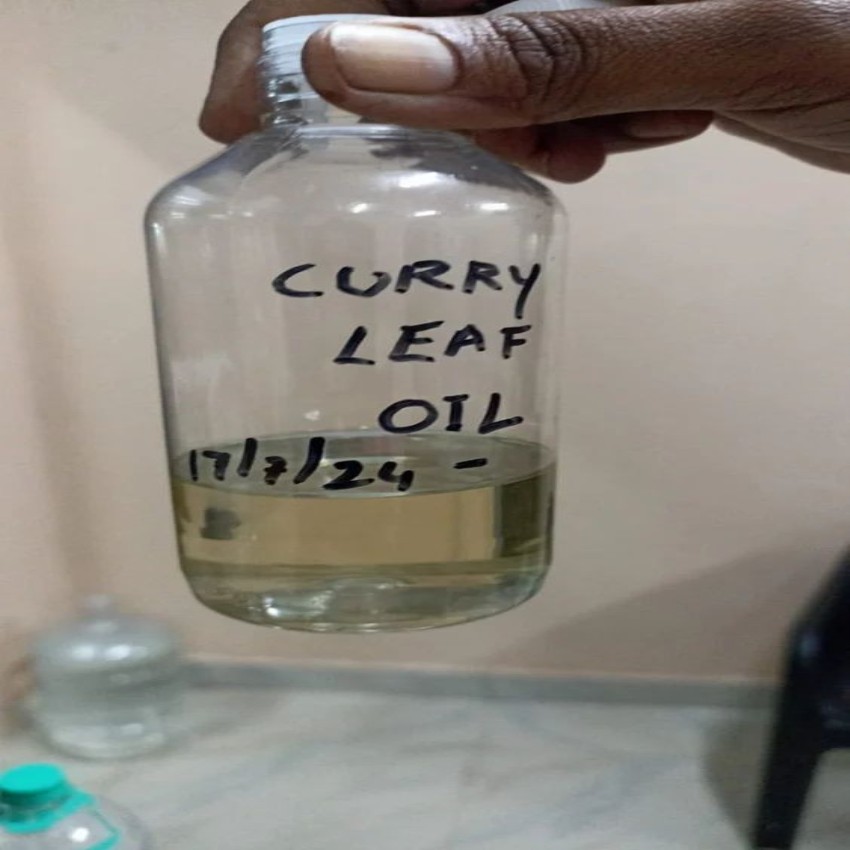

Curry Leaves Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

1,65,000.00

/ Metric Ton

| General Details: | |

| Model | Curry Leaves Oils Distillation Plants, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | yes |

| Power Source | yes |

| Voltage | yes |

| Usage/Application | yes |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | yes |

Blue Tansy Flower & Buds Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

15,00,000.00

| General Details: | |

| Model | Blue Tansy Flower & Buds Oils Distillation Plants, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | yes |

| Power Source | yes |

| Voltage | yes |

| Usage/Application | yes |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | yes |

Hemp / Cannabis Leaves Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

8,50,000.00

| General Details: | |

| Model | Hemp / Cannabis Leaves Oils Distillation Plants, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | yes |

| Power Source | yes |

| Voltage | yes |

| Usage/Application | yes |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | yes |

Cannabis Leaves Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

25,00,000.00

| General Details: | |

| Model | Cannabis Leaves Oils Distillation Plants, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | yes |

| Power Source | yes |

| Voltage | yes |

| Usage/Application | yes |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | yes |

Aromatic Oil Distillation Plant Manufacturer In India

Brand:

Others

Price ₹

7,00,000.00

| General Details: | |

| Model | Aromatic Oil Distillation Plant Manufacturer In India |

| Automation Grade | Semi Automatic |

| Frequency | 50 / 60 HZ |

| Power Source | ELECTRICAL AND WOOD |

| Voltage | 415 |

| Others: | |

| Capacity | 100 TPD |

| Country of Origin | Made in India |

Tulsi Oil Distillation Plant

Brand:

Others

Price ₹

3,00,000.00

| General Details: | |

| Model | Tulsi Oil Distillation Plant |

| Automation Grade | Semi Automatic |

| Frequency | 50 HZ |

| Power Source | ELECTRICAL |

| Voltage | 220 V |

| Usage/Application | TULSI OIL DISTILLATION PLANT |

| Others: | |

| Capacity | 10 TPD |

| Country of Origin | Made in India |

Rose Oil Distillation Plant

Brand:

Others

Price ₹

7,80,000.00

| General Details: | |

| Model | Rose Oil Distillation Plant |

| Automation Grade | Semi Automatic |

| Frequency | 50 / 60 HZ |

| Power Source | LPG GAS |

| Usage/Application | DISTILLATION |

| Others: | |

| Capacity | 10 TPD |

| Country of Origin | Made in India |

Rose Hydrosol Distillation Plant

Brand:

Others

Price ₹

1,48,000.00

| General Details: | |

| Model | Rose Hydrosol Distillation Plant |

| Automation Grade | Semi Automatic |

| Frequency | 50 / 60 HZ |

| Power Source | LPG GAS / ELECTRICAL / SOLID FUEL |

| Usage/Application | HYDROSOL |

| Others: | |

| Capacity | 10 TPD |

| Country of Origin | Made in India |

Mini Essential Oil Distillation Plant

Brand:

Others

Price ₹

12,50,000.00

| General Details: | |

| Model | Mini Essential Oil Distillation Plant |

| Automation Grade | Semi Automatic |

| Frequency | 50 Hz |

| Power Source | Electric |

| Voltage | 220 V |

| Usage/Application | Industrial |

| Others: | |

| Capacity | 50 TPD |

Mini Aromatic Oil Distillation Equipment

Brand:

Others

Price ₹

9,80,000.00

| General Details: | |

| Model | Mini Aromatic Oil Distillation Equipment |

| Automation Grade | Semi Automatic |

| Frequency | 60 Hz |

| Power Source | Electric |

| Voltage | 220 V |

| Usage/Application | Industrial |

| Others: | |

| Capacity | 50 TPD |

Oil Distillation Plant Manufacturers In India

Brand:

Others

Price ₹

3,00,000.00

| General Details: | |

| Model | Oil Distillation Plant Manufacturers In India |

| Automation Grade | Semi Automatic |

| Power Source | Electrical |

| Voltage | 415 |

| Usage/Application | Distillation |

| Others: | |

| Capacity | 100 TPD |

| Country of Origin | Made in India |

Essential Oil Field Distillation Unit

Brand:

Others

Price ₹

7,00,000.00

| General Details: | |

| Model | Essential Oil Field Distillation Unit |

| Automation Grade | Semi Automatic |

| Frequency | 50 HZ |

| Voltage | 415 |

| Usage/Application | DISTILLATION PLANT |

| Others: | |

| Capacity | 500 TPD |

| Country of Origin | Made in India |

Essential Oil Distillation Unit

Brand:

Others

Price ₹

1,70,000.00

| General Details: | |

| Model | Essential Oil Distillation Unit |

| Automation Grade | Semi Automatic |

| Frequency | 50 HZ |

| Power Source | WOOD / GRASS / ELECTRICAL |

| Voltage | 220 / 415 V |

| Usage/Application | STEAM DISTILLATION |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

Automatic Essential Oil Distillation Plant

Brand:

Others

Price ₹

8,00,000.00

| General Details: | |

| Model | Automatic Essential Oil Distillation Plant |

| Automation Grade | Automatic |

| Frequency | 50 HZ |

| Power Source | WOOD |

| Voltage | 220 / 415 V |

| Usage/Application | STEAM DISTILLATION |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

Essential Oil Distillation

Brand:

Others

Price ₹

1,80,000.00

| General Details: | |

| Model | Essential Oil Distillation |

| Automation Grade | Semi Automatic |

| Frequency | 50 HZ |

| Voltage | 415 V |

| Usage/Application | DISTILLATION |

| Others: | |

| Capacity | 500 TPD |

| Country of Origin | Made in India |

Small Scale Essential Oil Distillation Unit, Capacity : 5 TPD

Brand:

Others

Price ₹

2,00,000.00

| General Details: | |

| Model | Small Scale Essential Oil Distillation Unit, Capacity : 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | 50 HZ |

| Power Source | GAS / ELECTRICAL |

| Voltage | 220 / 415 V |

| Usage/Application | STEAM / HYDRO DISTILLATION |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

Essential Oil Distillation Machine

Brand:

Others

Price ₹

7,00,000.00

| General Details: | |

| Model | Essential Oil Distillation Machine |

| Automation Grade | Semi Automatic |

| Frequency | 50 HZ |

| Power Source | FIRE WOOD / ELECTRIACL |

| Voltage | 220 / 415 V |

| Usage/Application | STEAM DISTILLATION |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

Essential Oil Distillation Plant Manufacturers In India

Brand:

Others

Price ₹

9,00,000.00

| General Details: | |

| Model | Essential Oil Distillation Plant Manufacturers In India |

| Automation Grade | Semi Automatic |

| Frequency | 50 / 60 HZ |

| Voltage | 220 / 415 V |

| Usage/Application | DISTILLATION |

| Others: | |

| Capacity | 100 TPD |

| Country of Origin | Made in India |

Aromatic Oil Distillation Plant

Brand:

Others

Price ₹

13,00,000.00

| General Details: | |

| Model | Aromatic Oil Distillation Plant |

| Automation Grade | Semi Automatic |

| Frequency | 50 HZ |

| Power Source | WOOD, DIESEL, GAS, ELECTRICITY |

| Voltage | 220 / 415 V |

| Usage/Application | STEAM DISTILLATION PLANT |

| Others: | |

| Capacity | 100 TPD |

| Country of Origin | Made in India |

Sandal Wood Oil Distillation Plant

Brand:

Others

Price ₹

10,00,000.00

| General Details: | |

| Model | Sandal Wood Oil Distillation Plant |

| Automation Grade | Semi Automatic |

| Frequency | 50 / 60 HZ |

| Power Source | Steam |

| Voltage | 415V |

| Usage/Application | Sandal Wood Oil Distillation Plant |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

Essential Oil Distillation Plant

Brand:

Others

Price ₹

2,00,000.00

| General Details: | |

| Model | Essential Oil Distillation Plant |

| Automation Grade | Semi Automatic |

| Frequency | 50 HZ |

| Power Source | ELECTRICAL |

| Voltage | 415 |

| Usage/Application | PILOT TYPE DISTILLATION UNIT |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

Agar Wood Oil Distillation Plant

Brand:

Others

Price ₹

12,00,000.00

| General Details: | |

| Model | Agar Wood Oil Distillation Plant |

| Automation Grade | Semi Automatic |

| Frequency | 50 / 60 hz |

| Power Source | Gas fired |

| Voltage | 415 |

| Usage/Application | Agar wood oil Distillation Plant |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

Lemon Grass Essential Oil Distillation Plant

Brand:

Others

Price ₹

8,00,000.00

| General Details: | |

| Model | Lemon Grass Essential Oil Distillation Plant |

| Automation Grade | Semi Automatic |

| Frequency | 50 / 60 HZ |

| Power Source | Electrical |

| Voltage | 415 |

| Usage/Application | Aromatic Oil Distillation Plant |

| Others: | |

| Capacity | 50 TPD |

| Country of Origin | Made in India |

Sandal Wood Distillation Plant

Brand:

Others

Price ₹

10,00,000.00

| General Details: | |

| Model | Sandal Wood Distillation Plant |

| Material | ss |

| Automation Grade | Semi-Automatic |

| Frequency | 50 |

| Voltage | 415 |

| Others: | |

| Brand | MECH O TECH |

| Capacity | upto 10 tons |

| Country of Origin | Made in India |

Vetiver Essential Oil Distillation Unit

Brand:

Others

Price ₹

5,00,000.00

| General Details: | |

| Model | Vetiver Essential Oil Distillation Unit |

| Automation Grade | Semi Automatic |

| Frequency | 50 Hz |

| Voltage | 220V |

| Usage/Application | Vetiver Essential Oil Steam Distillation Plant |

| Others: | |

| Capacity | 50 TPD |

| Country of Origin | Made in India |

Citronella Oil Distillation Plant

Brand:

Others

Price ₹

5,50,000.00

| General Details: | |

| Model | Citronella Oil Distillation Plant |

| Automation Grade | Semi Automatic |

| Frequency | 50 Hz |

| Power Source | Electrical |

| Voltage | 220V |

| Usage/Application | Citronella Oil Distillation Plant |

| Others: | |

| Capacity | 100 TPD |

| Country of Origin | Made in India |

Geranium Oil Distillation Plant

Brand:

Others

Price ₹

5,80,000.00

| General Details: | |

| Model | Geranium Oil Distillation Plant |

| Automation Grade | Semi Automatic |

| Frequency | 50 Hz |

| Power Source | Electrical / Wood |

| Usage/Application | Distillation |

| Others: | |

| Capacity | 100 TPD |

| Country of Origin | Made in India |

Field Distillation Unit For Essential Oil

Brand:

Others

Price ₹

6,00,000.00

| General Details: | |

| Model | Field Distillation Unit For Essential Oil |

| Automation Grade | Semi Automatic |

| Voltage | 415 |

| Others: | |

| Business Type | Manufacturer, Supplier |

| Capacity | 500 TPD |

| Condition | Brand New |

| Country of Origin | Made in India |

| Features | Low pressure drop, energy efficient, no power needed option |

| I Deal In | New Only |

| Usage/Application | Essential oils from herbs, leaves, roots |

Small Essential Oil Distillation

Brand:

Others

Price ₹

5,90,000.00

| General Details: | |

| Model | Small Essential Oil Distillation |

| Automation Grade | Semi Automatic |

| Frequency | 50 HZ |

| Power Source | GAS / ELECTRICAL |

| Voltage | 220 / 415 V |

| Usage/Application | STEAM / HYDRO DISTILLATION |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

Small Scale Aromatic Oil Distillation Equipment

Brand:

Others

Price ₹

1,75,000.00

| General Details: | |

| Model | Small Scale Aromatic Oil Distillation Equipment |

| Automation Grade | Semi Automatic |

| Frequency | 50 Hz |

| Power Source | Electric |

| Voltage | 220 V |

| Usage/Application | Industrial |

| Others: | |

| Capacity | 50 TPD |

Curry Leaves Distillation Plant

Brand:

Others

Price ₹

16,50,000.00

| General Details: | |

| Model | Curry Leaves Distillation Plant |

| Automation Grade | Semi Automatic |

| Frequency | 50 / 60 HZ |

| Design | Customized |

| Usage/Application | DISTILLATION / HYDROSOL |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

Mint Oil Distillation Unit

Brand:

Others

Price ₹

2,50,000.00

| General Details: | |

| Model | Mint Oil Distillation Unit |

| Automation Grade | Semi Automatic |

| Frequency | 50 / 60 HZ |

| Voltage | 220 / 415 / 440 V |

| Usage/Application | Oil Distillation |

| Others: | |

| Capacity | 10 TPD |

| Country of Origin | Made in India |

Ginger Oil Distillation Plant

Brand:

Others

Price ₹

3,00,000.00

| General Details: | |

| Model | Ginger Oil Distillation Plant |

| Automation Grade | Semi Automatic |

| Frequency | 50 / 60 HZ |

| Voltage | 220 / 415 /440 V |

| Usage/Application | Oil Distillation |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

Cinnamon (Leaves / Bark) Spices Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

7,50,000.00

| General Details: | |

| Model | Cinnamon (Leaves / Bark) Spices Oils Distillation Plants, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | yes |

| Power Source | yes |

| Voltage | yes |

| Usage/Application | yes |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | yes |

Clove Buds Spices Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

3,50,000.00

| General Details: | |

| Model | Clove Buds Spices Oils Distillation Plants, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | yes |

| Power Source | yes |

| Voltage | yes |

| Usage/Application | yes |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | yes |

Turmeric Leaf Oil Distillation Plant

Brand:

Others

Price ₹

2,50,000.00

| General Details: | |

| Model | Turmeric Leaf Oil Distillation Plant |

| Automation Grade | Semi Automatic |

| Frequency | 50 / 60 hz |

| Voltage | 220 / 415 / 440 V |

| Usage/Application | Turmeric Oil Distillation |

| Others: | |

| Capacity | 10 TPD |

| Country of Origin | Made in India |

Black Pepper Spice Oil Distillation Plant

Brand:

Others

Price ₹

10,00,000.00

| General Details: | |

| Model | Black Pepper Spice Oil Distillation Plant |

| Automation Grade | Semi Automatic |

| Frequency | 60Hz |

| Power Source | Electrical / Steam |

| Voltage | 415V |

| Usage/Application | Black Pepper Distillation Plant |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

Cardmom (Seed) Spices Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

8,00,000.00

| General Details: | |

| Model | Cardmom (Seed) Spices Oils Distillation Plants, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | yes |

| Usage/Application | yes |

| Others: | |

| Capacity | 5 TPD |

| Power Consumption | yes |

Cassia (Bark) Spices Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

8,00,000.00

| General Details: | |

| Model | Cassia (Bark) Spices Oils Distillation Plants, Capacity: 5 TPD |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Frequency | yes |

| Power Source | yes |

| Voltage | yes |

| Design | Customization |

| Usage/Application | yes |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | yes |

Bay Laurel Spices Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

50,00,000.00

| General Details: | |

| Model | Bay Laurel Spices Oils Distillation Plants, Capacity: 5 TPD |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Frequency | yes |

| Power Source | yes |

| Voltage | yes |

| Design | Customization |

| Usage/Application | yes |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | yes |

Spice Oil Distillation Plant, Capacity

Brand:

Others

Price ₹

15,00,000.00

| General Details: | |

| Model | Spice Oil Distillation Plant, Capacity |

| Automation Grade | Semi Automatic |

| Frequency | 50 / 60 hz |

| Power Source | Electrical |

| Voltage | 220 / 415 volts |

| Usage/Application | Spice oil distillation |

| Others: | |

| Capacity | 10 TPD |

| Country of Origin | Made in India |

Cinnamon Bark Oil Distillation Plant

Brand:

Others

Price ₹

5,00,000.00

| General Details: | |

| Model | Cinnamon Bark Oil Distillation Plant |

| Automation Grade | Semi Automatic |

| Frequency | 50 / 60 hz |

| Voltage | 220 / 415 / 440 V |

| Usage/Application | Spice Oil Distillation |

| Others: | |

| Capacity | 10 TPD |

| Country of Origin | Made in India |

Cinnamon Leaf Oil Distillation Plant

Brand:

Others

Price ₹

5,10,000.00

| General Details: | |

| Model | Cinnamon Leaf Oil Distillation Plant |

| Automation Grade | Semi Automatic |

| Frequency | 50 / 60 hz |

| Voltage | 220 / 415 / 440 V |

| Usage/Application | Spice Oil Distillation |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

Turmeric Oil Distillation Plant

Brand:

Others

Price ₹

2,50,000.00

| General Details: | |

| Model | Turmeric Oil Distillation Plant |

| Automation Grade | Semi Automatic |

| Frequency | 50 / 60 hz |

| Voltage | 220 / 415 / 440 V |

| Usage/Application | Essential Oil Distillation |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

Nutmeg Spices Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

5,00,000.00

| General Details: | |

| Model | Nutmeg Spices Oils Distillation Plants, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | yes |

| Power Source | yes |

| Voltage | yes |

| Usage/Application | yes |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | yes |

Turmeric Spices Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

8,00,000.00

| General Details: | |

| Model | Turmeric Spices Oils Distillation Plants, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | yes |

| Power Source | yes |

| Voltage | yes |

| Usage/Application | yes |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | yes |

Cinnamon Spice Oil Distillation Plant , Capacity : 50 tons

Brand:

Others

Price ₹

5,30,000.00

| General Details: | |

| Model | Cinnamon Spice Oil Distillation Plant , Capacity : 50 tons |

| Material | Stainless Steel |

| Automation Grade | Automatic |

| Frequency | 50 Hz |

| Voltage | 220V |

| Usage/Application | Used For Oil Refining, Water Purification, And The Creation Of Alcoholic Beverages. |

| Others: | |

| Capacity | 50 tons |

| Power Consumption | 1.5 kW |

Turmeric Leaf Oil Distillation Plant , Frequency : 50 Hz

Brand:

Others

Price ₹

7,50,000.00

| General Details: | |

| Model | Turmeric Leaf Oil Distillation Plant , Frequency : 50 Hz |

| Automation Grade | Semi Automatic |

| Frequency | 50 Hz |

| Power Source | Electrical And Wood |

| Voltage | Single Phase |

| Usage/Application | Turmeric Leaf Oil Steam Distillation Unit |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

Spice Distillation Plant

Brand:

Others

Price ₹

15,00,000.00

| General Details: | |

| Model | Spice Distillation Plant |

| Automation Grade | Semi Automatic |

| Frequency | 50 / 60 HZ |

| Power Source | ELECTRICAL |

| Voltage | 220 / 415 V |

| Usage/Application | SPICE OIL DISTILLATION |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

Clove Leaf Oil Distillation Plant

Brand:

Others

Price ₹

10,00,000.00

| General Details: | |

| Model | Clove Leaf Oil Distillation Plant |

| Automation Grade | Semi Automatic |

| Frequency | 50Hz |

| Power Source | Electrical And Wood |

| Voltage | 415V |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

Garlic (Bulb) Spices Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

5,00,000.00

| General Details: | |

| Model | Garlic (Bulb) Spices Oils Distillation Plants, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | yes |

| Power Source | yes |

| Voltage | yes |

| Usage/Application | yes |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | yes |

Ginger Spices Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

5,40,000.00

| General Details: | |

| Model | Ginger Spices Oils Distillation Plants, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | yes |

| Power Source | yes |

| Voltage | yes |

| Usage/Application | yes |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | yes |

Fennel Spices Oils Distillation Plants, Capacity: 100 TPD

Brand:

Others

Price ₹

8,10,000.00

| General Details: | |

| Model | Fennel Spices Oils Distillation Plants, Capacity: 100 TPD |

| Automation Grade | Semi Automatic |

| Frequency | yes |

| Power Source | yes |

| Voltage | yes |

| Usage/Application | yes |

| Others: | |

| Capacity | 100 TPD |

| Country of Origin | Made in India |

| Power Consumption | yes |

Cumin (Seed) Spices Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

2,60,000.00

| General Details: | |

| Model | Cumin (Seed) Spices Oils Distillation Plants, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | yes |

| Power Source | yes |

| Voltage | yes |

| Usage/Application | yes |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | yes |

Lemon Grass Oil Stream Distillation Plant, Capacity: 5 TPD

Brand:

Others

Price ₹

10,00,000.00

| General Details: | |

| Model | Lemon Grass Oil Stream Distillation Plant, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | Yes |

| Power Source | Yes |

| Usage/Application | Yes |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | Yes |

Coriander (Seed) Spices Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

5,80,000.00

| General Details: | |

| Model | Coriander (Seed) Spices Oils Distillation Plants, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | yes |

| Power Source | yes |

| Voltage | yes |

| Usage/Application | yes |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | yes |

Black Pepper Spices Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

10,00,000.00

| General Details: | |

| Model | Black Pepper Spices Oils Distillation Plants, Capacity: 5 TPD |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Frequency | yes |

| Power Source | yes |

| Voltage | yes |

| Design | Customization |

| Usage/Application | yes |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | yes |

Ajwain Spices Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

8,00,000.00

| General Details: | |

| Model | Ajwain Spices Oils Distillation Plants, Capacity: 5 TPD |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Frequency | yes |

| Power Source | yes |

| Voltage | yes |

| Usage/Application | yes |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | yes |

Ledum / Labrador Tea / Greenland Moss Leaves Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

5,80,000.00

| General Details: | |

| Model | Ledum / Labrador Tea / Greenland Moss Leaves Oils Distillation Plants, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | yes |

| Power Source | yes |

| Voltage | yes |

| Usage/Application | yes |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | yes |

Magnolia / White Champac (Flowers / Blossoms) Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

10,00,000.00

| General Details: | |

| Model | Magnolia / White Champac (Flowers / Blossoms) Oils Distillation Plants, Capacity: 5 TPD |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Frequency | yes |

| Power Source | yes |

| Voltage | yes |

| Design | Customization |

| Usage/Application | yes |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | yes |

Geranium oil steam distillaton plant, Capacity: 5 TPD

Brand:

Others

Price ₹

13,00,000.00

| General Details: | |

| Model | Geranium oil steam distillaton plant, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | yyes |

| Power Source | yes |

| Usage/Application | yes |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | yes |

Frankincense(Gum) oil distillation plant, Capacity: 5 TPD

Brand:

Others

Price ₹

15,00,000.00

| General Details: | |

| Model | Frankincense(Gum) oil distillation plant, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | Yes |

| Power Source | Yes |

| Usage/Application | Yes |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | Yes |

Helichrysum Italicum /Immortelle Flower & Buds Oils Distillation Plants

Brand:

Others

Price ₹

5,50,000.00

| General Details: | |

| Model | Helichrysum Italicum /Immortelle Flower & Buds Oils Distillation Plants |

| Automation Grade | Semi Automatic |

| Frequency | YES |

| Power Source | YES |

| Voltage | YES |

| Usage/Application | YES |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | YES |

Jasmine Grandiflorum Flower & Buds Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

75,00,000.00

| General Details: | |

| Model | Jasmine Grandiflorum Flower & Buds Oils Distillation Plants, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | YES |

| Power Source | YES |

| Voltage | YES |

| Usage/Application | YES |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | YES |

Jasmine Sambac Flower & Buds Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

7,70,000.00

| General Details: | |

| Model | Jasmine Sambac Flower & Buds Oils Distillation Plants, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | yes |

| Power Source | yes |

| Usage/Application | yes |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | yes |

Kewada Flower & Buds Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

13,00,000.00

| General Details: | |

| Model | Kewada Flower & Buds Oils Distillation Plants, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | YES |

| Power Source | YES |

| Voltage | YES |

| Usage/Application | YES |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | YES |

Lavandin Flower & Buds Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

10,00,000.00

| General Details: | |

| Model | Lavandin Flower & Buds Oils Distillation Plants, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | yes |

| Power Source | yes |

| Voltage | yes |

| Usage/Application | yes |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | yes |

German Chamomile / Blue Chamomile Flower & Buds Oils Distillation Plants

Brand:

Others

Price ₹

14,00,000.00

| General Details: | |

| Model | German Chamomile / Blue Chamomile Flower & Buds Oils Distillation Plants |

| Automation Grade | Semi Automatic |

| Frequency | yes |

| Power Source | yes |

| Voltage | yes |

| Usage/Application | yes |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | yes |

Golden Rod Flower & Buds Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

12,30,000.00

| General Details: | |

| Model | Golden Rod Flower & Buds Oils Distillation Plants, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | yes |

| Power Source | yes |

| Voltage | yes |

| Usage/Application | yes |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | yes |

Tube Rose Flower & Buds Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

2,00,000.00

| General Details: | |

| Model | Tube Rose Flower & Buds Oils Distillation Plants, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | yes |

| Power Source | yes |

| Voltage | yes |

| Usage/Application | yes |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | yes |

YlangYlang Flower & Buds Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

5,00,000.00

| General Details: | |

| Model | YlangYlang Flower & Buds Oils Distillation Plants, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | YES |

| Power Source | YES |

| Voltage | YES |

| Usage/Application | YES |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Power Consumption | YES |

Flower & Buds Oils Distillation Plants, Capacity: 5 TPD

Brand:

Others

Price ₹

2,10,000.00

| General Details: | |

| Model | Flower & Buds Oils Distillation Plants, Capacity: 5 TPD |