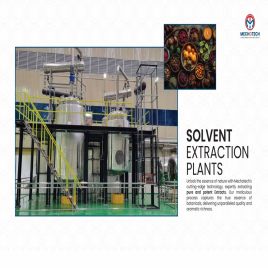

Solvent Extraction Plant

SHILAJIT AQUA EXTRACTION PLANT, Capacity: 100 TPD

Brand:

Others

Price ₹

20,00,000.00

| General Details: | |

| Model | SHILAJIT AQUA EXTRACTION PLANT, Capacity: 100 TPD |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 415 |

| Capacity | 100 TPD |

| Usage/Application | Extract |

| Machine Type | Aqua Extraction |

| Others: | |

| Brand | MECH O TECH |

| Country of Origin | Made in India |

| I Deal In | New Only |

| Installation Services | Yes |

Agarwood Absolute Solvent Extraction Plant

Brand:

Others

Price ₹

50,00,000.00

| General Details: | |

| Model | Agarwood Absolute Solvent Extraction Plant |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 220 / 415 / 380 |

| Capacity | 100 TPD |

| Usage/Application | AGARWOOD ABSOLUTE |

| Machine Type | TURN KEY |

| Power Source | ELECTRICAL / WOOD |

| Design Type | TAILORE MADE |

| Others: | |

| Brand | MECH O TECH |

| Installation Services | Yes |

| Recommended Order Quantity | 1 |

| Country of Origin | Made in India |

| Business Type | Manufacturer, Supplier |

| Condition | Brand New |

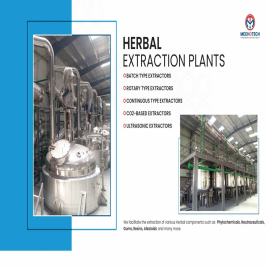

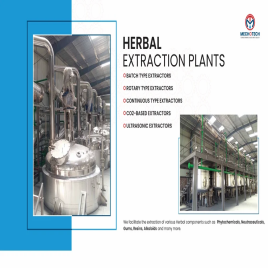

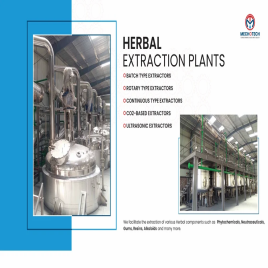

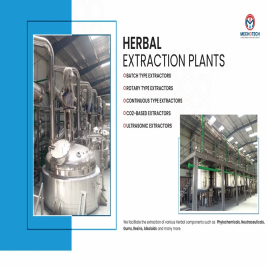

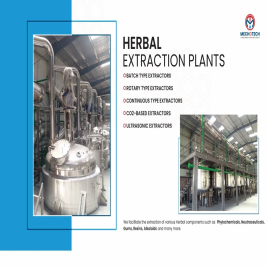

Andrographis Paniculata Extraction Plant Manufacturers

Brand:

Others

Price ₹

25,00,000.00

| General Details: | |

| Model | Andrographis Paniculata Extraction Plant Manufacturers |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 240V |

| Driven Type | Electrical |

| Motor | yes |

| Capacity | 100 TPD |

| Usage/Application | Herbal Extraction |

| Machine Type | Solvent Extraction |

| Power Source | Electric |

| Design Type | yes |

| Thickness Of Flakes | yes |

| Pressure | yes |

| Temperature Range | yes |

| Others: | |

| Brand | mechotech llp |

| Installation Services | Yes |

| Recommended Order Quantity | 1 |

Red Chilly Powder Extraction Plant Manufacturers, Capacity: 100 TPD

Brand:

Others

Price ₹

1,00,00,000.00

| General Details: | |

| Model | Red Chilly Powder Extraction Plant Manufacturers, Capacity: 100 TPD |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Capacity | 100 TPD |

| Others: | |

| Brand | Mechotechllp |

| Country of Origin | Made in India |

| Installation Services | Yes |

| Recommended Order Quantity | 1 |

Shilajit Extract Plant Manufacturers, Capacity: 100 TPD

Brand:

Others

Price ₹

35,00,000.00

| General Details: | |

| Model | Shilajit Extract Plant Manufacturers, Capacity: 100 TPD |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Capacity | 100 TPD |

| Others: | |

| Brand | Mechotech |

| Country of Origin | Made in India |

| Installation Services | Yes |

| Recommended Order Quantity | 1 |

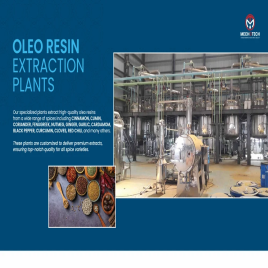

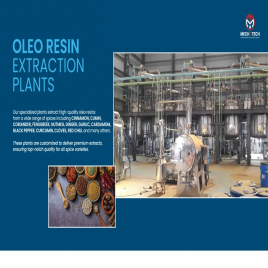

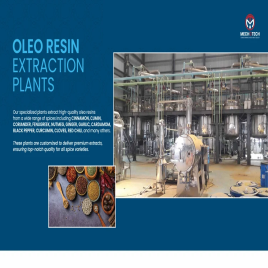

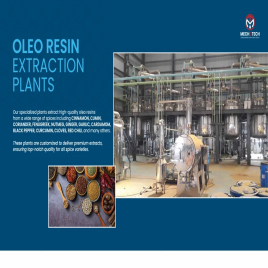

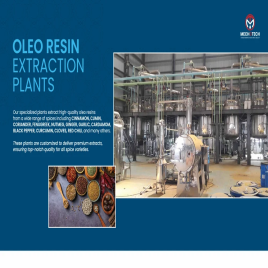

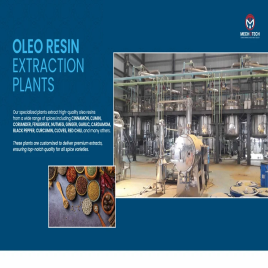

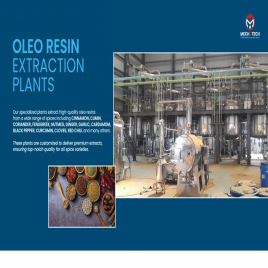

Mustard Oleoresin Extraction Plant, Capacity: 100 TPD

Brand:

Others

Price ₹

50,00,000.00

| General Details: | |

| Model | Mustard Oleoresin Extraction Plant, Capacity: 100 TPD |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 220 V |

| Capacity | 100 TPD |

| Usage/Application | Industrial |

| Machine Type | Mustard Oleoresin Extraction |

| Others: | |

| Frequency | 50 Hz |

Capsaicin Oleoresin Extraction Plant, Capacity: 100 TPD

Brand:

Others

Price ₹

50,00,000.00

| General Details: | |

| Model | Capsaicin Oleoresin Extraction Plant, Capacity: 100 TPD |

| Material | Stainless Steel |

| Automation Grade | Automatic |

| Voltage | 120V |

| Capacity | 100 TPD |

| Usage/Application | Industrial Use |

| Others: | |

| Country of Origin | Made in India |

| Frequency | 50Hz |

| Recommended Order Quantity | 2 |

| Phase | Single |

Spices Oleoresin Extraction Plant, Capacity: 100 TPD

Brand:

Others

Price ₹

50,00,000.00

| General Details: | |

| Model | Spices Oleoresin Extraction Plant, Capacity: 100 TPD |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 220 V |

| Capacity | 100 TPD |

| Usage/Application | Industrial |

| Machine Type | Oleoresin Extraction Plant |

| Power Source | Electric |

| Others: | |

| Frequency | 50 Hz |

| I Deal In | New Only |

Oleoresin Extraction Plant Manufacturers In Hyderabad

Brand:

Others

Price ₹

50,00,000.00

| General Details: | |

| Model | Oleoresin Extraction Plant Manufacturers In Hyderabad |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 220 V |

| Capacity | 100 TPD |

| Usage/Application | Industrial |

| Machine Type | Oleoresin Extraction Plant |

| Power Source | Electric |

| Others: | |

| Frequency | 50 Hz |

| I Deal In | New Only |

Cardmom Oleoresin Extraction Plant, Capacity: 100 TPD

Brand:

Others

Price ₹

50,00,000.00

| General Details: | |

| Model | Cardmom Oleoresin Extraction Plant, Capacity: 100 TPD |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 220 V |

| Capacity | 100 TPD |

| Usage/Application | Industrial |

| Machine Type | Cardmom Oleoresin Extraction |

| Power Source | Electric Source |

| Others: | |

| Frequency | 50 Hz |

| I Deal In | New Only |

Cumin Oleoresin Extraction Plant, Capacity: 100 TPD

Brand:

Others

Price ₹

50,00,000.00

| General Details: | |

| Model | Cumin Oleoresin Extraction Plant, Capacity: 100 TPD |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 220 V |

| Capacity | 100 TPD |

| Usage/Application | Industrial |

| Machine Type | Cumin Oleoresin Extraction |

| Power Source | Electric |

| Others: | |

| Frequency | 50 Hz |

| I Deal In | New Only |

Coriander Oleoresin Extraction Plant

Brand:

Others

Price ₹

50,00,000.00

| General Details: | |

| Model | Coriander Oleoresin Extraction Plant |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 220 V |

| Capacity | 100 TPD |

| Usage/Application | Industrial |

| Machine Type | Coriander Oleoresin Extraction |

| Power Source | Electric |

| Others: | |

| Frequency | 50 Hz |

| I Deal In | New Only |

Capsicum Oleoresin Extraction Plant, Capacity: 100 TPD

Brand:

Others

Price ₹

50,00,000.00

| General Details: | |

| Model | Capsicum Oleoresin Extraction Plant, Capacity: 100 TPD |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 120V |

| Capacity | 100 TPD |

| Usage/Application | Industrial Use |

| Power Source | Electric |

| Others: | |

| Frequency | 50 Hz |

| I Deal In | New Only |

| Recommended Order Quantity | 2 |

Bavachi Seed Extract Plant Manufacturers, Capacity: 100 TPD

Brand:

Others

Price ₹

50,00,000.00

| General Details: | |

| Model | Bavachi Seed Extract Plant Manufacturers, Capacity: 100 TPD |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 240V |

| Driven Type | Electrical |

| Motor | yes |

| Capacity | 100 TPD |

| Usage/Application | Herbal Extraction |

| Machine Type | Solvent Extraction |

| Power Source | Electric |

| Design Type | Yes |

| Thickness Of Flakes | yes |

| Pressure | yes |

| Temperature Range | yes |

| Others: | |

| Brand | Mechotechllp |

| Country of Origin | Made in India |

| Installation Services | Yes |

| Recommended Order Quantity | 1 |

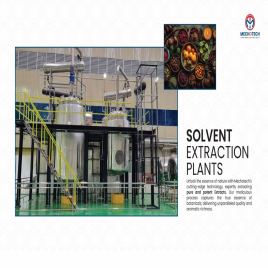

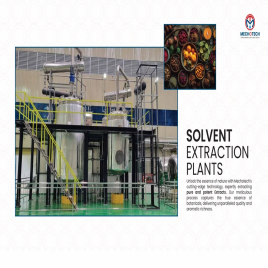

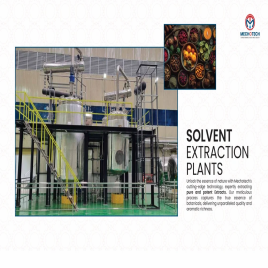

Solvent Extraction Systems

Brand:

Others

Price ₹

10,00,000.00

| General Details: | |

| Model | Solvent Extraction Systems |

| Material | SS 316 / 316L / 304 / MS |

| Voltage | 220 / 380 / 415 |

| Capacity | 10 KG TO ANY |

| Design Type | Customised |

| Others: | |

| Installation Services | YES |

| Recommended Order Quantity | 1 |

Adhatoda Vasica Extract Plant manufacturers

Brand:

Others

Price ₹

10,00,000.00

| General Details: | |

| Model | Adhatoda Vasica Extract Plant manufacturers |

| Others: | |

| Country of Origin | Made in India |

| End Uses | Customers |

| Form | Mechotechllp |

| Herbal | Extraction plant |

| Recommended Order Quantity | 1 |

| Packaging Type | Filim Packaging |

Extraction Machinery, Capacity: 100 TPD

Brand:

Others

Price ₹

10,00,000.00

| General Details: | |

| Model | Extraction Machinery, Capacity: 100 TPD |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 220 / 380 / 415 |

| Capacity | 100 TPD |

| Usage/Application | EXTRACTION |

| Power Source | ELECTRICAL |

| Design Type | CUSTOMIZED |

| Others: | |

| Brand | MECH O TECH |

| Installation Services | Yes |

| Recommended Order Quantity | 1 |

Mini Solvent Extraction Plant, Capacity: 100 TPD

Brand:

Others

Price ₹

5,00,000.00

| General Details: | |

| Model | Mini Solvent Extraction Plant, Capacity: 100 TPD |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 220 V |

| Capacity | 100 TPD |

| Usage/Application | Industrial |

| Machine Type | Solvent Extraction Plant |

| Power Source | Electric |

Solvent Extraction Plant, Stainless Steel

Brand:

Others

Price ₹

10,00,000.00

| General Details: | |

| Model | Solvent Extraction Plant, Stainless Steel |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 220 / 415 / 440 V |

| Capacity | 100 TPD |

| Usage/Application | Solvent Extraction |

| Design Type | Turn Key Project |

| Others: | |

| Brand | MECH O TECH |

| Installation Services | Yes |

| Recommended Order Quantity | 1 |

Sandal Wood Absolute Solvent Extraction unit, Capacity: 10 TPD

Brand:

Others

Price ₹

50,00,000.00

| General Details: | |

| Model | Sandal Wood Absolute Solvent Extraction unit, Capacity: 10 TPD |

| Automation Grade | Semi Automatic |

| Voltage | 220 / 415 / 380 |

| Capacity | 10 TPD |

| Usage/Application | Sandal wood absolute |

| Power Source | Electrical / Solid Fuel |

| Others: | |

| Country of Origin | Made in India |

| Frequency | 50 / 60 hz |

| Recommended Order Quantity | 1 |

Kaladana Seed Extraction Plant, Capacity: 100 TPD

Brand:

Others

Price ₹

15,00,000.00

| General Details: | |

| Model | Kaladana Seed Extraction Plant, Capacity: 100 TPD |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Capacity | 100 TPD |

| Others: | |

| Brand | Mechotechllp |

| Country of Origin | Made in India |

| Installation Services | Yes |

| Recommended Order Quantity | 1 |

Lutein Extraction Plant Manufacturers In India, Capacity: 100 TPD

Brand:

Others

Price ₹

10,00,000.00

| General Details: | |

| Model | Lutein Extraction Plant Manufacturers In India, Capacity: 100 TPD |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 220 V |

| Capacity | 100 TPD |

| Usage/Application | Industrial |

| Machine Type | Lutein Extraction Plant |

| Power Source | Electric |

| Others: | |

| Frequency | 60 Hz |

| I Deal In | New Only |

| Phase | Single Phase |

Marigold Extraction Plant Manufacturers In Hyderabad, Capacity: 500 TPD

Brand:

Others

Price ₹

10,00,000.00

| General Details: | |

| Model | Marigold Extraction Plant Manufacturers In Hyderabad, Capacity: 500 TPD |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 240 V |

| Capacity | 500 TPD |

| Usage/Application | Industrial |

| Machine Type | Extraction Plant |

| Power Source | Electric |

Marigold Solvent Extraction Plant Manufacturers In India, Capacity: 500 TPD

Brand:

Others

Price ₹

10,00,000.00

| General Details: | |

| Model | Marigold Solvent Extraction Plant Manufacturers In India, Capacity: 500 TPD |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 240 V |

| Driven Type | Electrical |

| Motor | yes |

| Capacity | 500 TPD |

| Usage/Application | Industrial |

| Machine Type | Solvent Extraction |

| Power Source | Electric |

| Design Type | yes |

| Thickness Of Flakes | yes |

| Pressure | yes |

| Temperature Range | yes |

| Others: | |

| Frequency | 60 Hz |

Marigold Solvent Extraction Palnt

Brand:

Others

Price ₹

10,00,000.00

| General Details: | |

| Model | Marigold Solvent Extraction Palnt |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 220 V |

| Capacity | 100 TPD |

| Usage/Application | Industrial |

| Machine Type | Solvent Extraction |

| Power Source | Electric |

| Others: | |

| Frequency | 50Hz |

| I Deal In | New Only |

| Phase | Single Phase |

Marigold Dye Extraction Equipment

Brand:

Others

Price ₹

10,00,000.00

| General Details: | |

| Model | Marigold Dye Extraction Equipment |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 220 V |

| Capacity | 100 TPD |

| Usage/Application | Industrial |

| Machine Type | Dye Extraction |

| Power Source | Electric |

| Others: | |

| Frequency | 50 Hz |

| I Deal In | New Only |

| Phase | Single Phase |

Marigold Pigment Extraction Plant, Capacity: 100 TPD

Brand:

Others

Price ₹

10,00,000.00

| General Details: | |

| Model | Marigold Pigment Extraction Plant, Capacity: 100 TPD |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 220V |

| Capacity | 100 TPD |

| Usage/Application | Industrial |

| Machine Type | Pigment Extraction |

| Power Source | Electric |

| Others: | |

| Frequency | 50 Hz |

| I Deal In | New Only |

Marigold Flower Extraction Plant, Capacity: 100 TPD

Brand:

Others

Price ₹

10,00,000.00

| General Details: | |

| Model | Marigold Flower Extraction Plant, Capacity: 100 TPD |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 220 V |

| Capacity | 100 TPD |

| Usage/Application | Industrial |

| Machine Type | Flower Extraction |

| Power Source | Electric |

| Others: | |

| Frequency | 50 Hz |

| I Deal In | New Only |

Milk Thistle Seed plant manufacturers in hyderabad, Capacity: 100 TPD

Brand:

Others

Price ₹

15,00,000.00

| General Details: | |

| Model | Milk Thistle Seed plant manufacturers in hyderabad, Capacity: 100 TPD |

| Material | Natural |

| Automation Grade | Semi Automatic |

| Capacity | 100 TPD |

| Others: | |

| 1 Ton | 2500000 |

| Brand | Mechotechllp |

| Country of Origin | Made in India |

| Installation Services | Yes |

| Recommended Order Quantity | 1 |

Boswellia Serrata Extract plant manufacturers, Capacity: 100 TPD

Brand:

Others

Price ₹

50,00,000.00

| General Details: | |

| Model | Boswellia Serrata Extract plant manufacturers, Capacity: 100 TPD |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 240V |

| Driven Type | yes |

| Motor | yes |

| Capacity | 100 TPD |

| Usage/Application | Herbal Extraction |

| Machine Type | Solvent Extraction |

| Power Source | Electric |

| Design Type | Yes |

| Thickness Of Flakes | yes |

| Pressure | yes |

| Temperature Range | yes |

| Others: | |

| Brand | MECHOTECH LLP |

| Country of Origin | Made in India |

| Installation Services | Yes |

| Recommended Order Quantity | 1 |

NICOTINE SULPHATE EXTRACTION PLANT, Capacity: 100 TPD

Brand:

Others

Price ₹

1,00,00,000.00

| General Details: | |

| Model | NICOTINE SULPHATE EXTRACTION PLANT, Capacity: 100 TPD |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 415 |

| Capacity | 100 TPD |

| Usage/Application | Tobacco extraction |

| Machine Type | Solvent Extraction |

| Power Source | Electricity |

| Design Type | Turnkey |

| Others: | |

| Brand | MECH O TECH |

| Country of Origin | Made in India |

| Frequency | 50 |

| Installation Services | Yes |

| Phase | 3 |

Oleoresin Extraction Equipment

Brand:

Others

Price ₹

10,00,000.00

| General Details: | |

| Model | Oleoresin Extraction Equipment |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 220 V |

| Capacity | 100 TPD |

| Usage/Application | Industrial |

| Machine Type | Extraction Equipment |

| Power Source | Electric |

| Others: | |

| Frequency | 50 Hz |

| I Deal In | New Only |

| Phase | Single Phase |

Mini Solvent Extraction Plant

Brand:

Others

Price ₹

5,00,000.00

| General Details: | |

| Model | Mini Solvent Extraction Plant |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 220 V |

| Capacity | 100 TPD |

| Usage/Application | Industrial |

| Machine Type | Solvent Extraction Plant |

| Power Source | Electric |

Continuous Solvent Extraction Plants, Capacity: 100 TPD

Brand:

Others

Price ₹

22,00,000.00

| General Details: | |

| Model | Continuous Solvent Extraction Plants, Capacity: 100 TPD |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 220 / 415 / 440 V |

| Capacity | 100 TPD |

| Usage/Application | Solvent Extraction |

| Design Type | Turn Key Project |

| Others: | |

| Brand | MECH O TECH |

| Country of Origin | Made in India |

| Installation Services | Yes |

Sandal Wood Absolute Solvent Extraction unit

Brand:

Others

Price ₹

50,00,000.00

| General Details: | |

| Model | Sandal Wood Absolute Solvent Extraction unit |

| Automation Grade | Semi Automatic |

| Voltage | 220 / 415 / 380 |

| Capacity | 10 TPD |

| Usage/Application | Sandal wood absolute |

| Power Source | Electrical / Solid Fuel |

| Others: | |

| Country of Origin | Made in India |

| Frequency | 50 / 60 hz |

Kaladana Seed Extraction Plant

Brand:

Others

Price ₹

15,00,000.00

| General Details: | |

| Model | Kaladana Seed Extraction Plant |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Capacity | 100 TPD |

| Others: | |

| Brand | Mechotechllp |

| Country of Origin | Made in India |

| Installation Services | Yes |

Bavachi Seed Extract Plant Manufacturers

Brand:

Others

Price ₹

50,00,000.00

| General Details: | |

| Model | Bavachi Seed Extract Plant Manufacturers |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 240V |

| Driven Type | Electrical |

| Motor | yes |

| Capacity | 100 TPD |

| Usage/Application | Herbal Extraction |

| Machine Type | Solvent Extraction |

| Power Source | Electric |

| Design Type | Yes |

| Thickness Of Flakes | yes |

| Pressure | yes |

| Temperature Range | yes |

| Others: | |

| Brand | Mechotechllp |

| Country of Origin | Made in India |

| Installation Services | Yes |

Solvent Extraction System

Brand:

Others

Price ₹

10,00,000.00

| General Details: | |

| Model | Solvent Extraction System |

| Material | SS 316 / 316L / 304 / MS |

| Voltage | 220 / 380 / 415 |

| Capacity | 10 KG TO ANY |

| Design Type | Customised |

| Others: | |

| Installation Services | YES |

Adhatoda Vasica Extract Plant manufacturer

Brand:

Others

Price ₹

10,00,000.00

| General Details: | |

| Model | Adhatoda Vasica Extract Plant manufacturer |

| Others: | |

| Country of Origin | Made in India |

| End Uses | Customers |

| Form | Mechotechllp |

| Herbal | Extraction plant |

| Packaging Type | Filim Packaging |

Extraction Machinery

Brand:

Others

Price ₹

10,00,000.00

| General Details: | |

| Model | Extraction Machinery |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 220 / 380 / 415 |

| Capacity | 100 TPD |

| Usage/Application | EXTRACTION |

| Power Source | ELECTRICAL |

| Design Type | CUSTOMIZED |

| Others: | |

| Brand | MECH O TECH |

| Installation Services | Yes |

Bamboo extraction plant manufacturing

Brand:

Others

Price ₹

40,00,000.00

| General Details: | |

| Model | Bamboo extraction plant manufacturing |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 240V |

| Driven Type | Electrical |

| Motor | yes |

| Capacity | Customization |

| Usage/Application | Herbal Extraction |

| Machine Type | Solvent Extraction |

| Power Source | Electrical |

| Design Type | yes |

| Thickness Of Flakes | yes |

| Pressure | yes |

| Temperature Range | yes |

| Others: | |

| Brand | MECHOTECH LLP |

| Installation Services | Yes |

Chaste Berry Extraction plant manufacturer

Brand:

Others

Price ₹

70,00,000.00

| General Details: | |

| Model | Chaste Berry Extract plant manufacturer |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 240V |

| Driven Type | Electrical |

| Motor | yes |

| Capacity | Customization |

| Usage/Application | Herbal Extraction |

| Machine Type | Solvent Extraction |

| Power Source | Electric |

| Design Type | yes |

| Thickness Of Flakes | yes |

| Pressure | yes |

| Temperature Range | yes |

| Others: | |

| Brand | MECHOTECH LLP |

| Installation Services | Yes |

Fenugreek Seed Extraction Plant, Capacity: 100 TPD

Brand:

Others

Price ₹

15,00,000.00

| General Details: | |

| Model | Fenugreek Seed Extraction Plant, Capacity: 100 TPD |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Capacity | 100 TPD |

| Usage/Application | Yes |

| Machine Type | Yes |

| Power Source | Yes |

| Design Type | Yes |

| Others: | |

| Brand | Yes |

| Installation Services | Yes |

Cocoa Beans Extraction Plant, Capacity: 100 TPD

Brand:

Others

Price ₹

15,00,000.00

| General Details: | |

| Model | Cocoa Beans Extraction Plant, Capacity: 100 TPD |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Capacity | 100 TPD |

| Usage/Application | Yes |

| Machine Type | Yes |

| Power Source | Yes |

| Design Type | Yes |

| Others: | |

| Brand | Yes |

| Installation Services | Yes |

Liquid Solvent Oil Extraction Plant, Capacity: 100 TPD

Brand:

Others

Price ₹

10,00,000.00

| General Details: | |

| Model | Liquid Solvent Oil Extraction Plant, Capacity: 100 TPD |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Capacity | 100 TPD |

| Usage/Application | Yes |

| Machine Type | Yes |

| Power Source | Yes |

| Design Type | Yes |

| Others: | |

| Brand | Yes |

| Installation Services | Yes |

Solvent Extraction Plant, Capacity: 100 TPD

Brand:

Others

Price ₹

15,00,000.00

| General Details: | |

| Model | Solvent Extraction Plant, Capacity: 100 TPD |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Capacity | 100 TPD |

| Usage/Application | Yes |

| Machine Type | Yes |

| Power Source | Yes |

| Design Type | Yes |

| Others: | |

| Brand | Yes |

| Installation Services | Yes |

Nutraceutical Powder Plant, Capacity: 50, Automation Grade: Semi-Automatic

Brand:

Others

Price ₹

10,00,000.00

| General Details: | |

| Model | Nutraceutical Powder Plant, Capacity: 50, Automation Grade: Semi-Automatic |

| Automation Grade | Semi-Automatic |

| Capacity | 50 |

| Power Source | Yes |

| Others: | |

| Brand | Yes |

| Country of Origin | Made in India |

| Machine Body Material | Yes |

| Phase | Yes |

| Power Consumption | Yes |

SEMI AUTOMATIC SOLVENT EXTRACTION PLANT, Capacity: 200 TPD

Brand:

Others

Price ₹

5,00,000.00

| General Details: | |

| Model | SEMI AUTOMATIC SOLVENT EXTRACTION PLANT, Capacity: 200 TPD |

| Material | Stainless Steel |

| Automation Grade | Semi-Automatic |

| Voltage | 220V |

| Capacity | 200 TPD |

| Usage/Application | Where Oil Is Extracted From Oil Seeds Like Soybean, Sunflower, Cottonseed, Other Oil Seeds |

| Machine Type | Solvent Extraction |

| Power Source | Electric |

| Others: | |

| Frequency | 50 Hz |

Shilajit Aqua Extraction Plant

Brand:

Others

Price ₹

20,00,000.00

| General Details: | |

| Model | SHILAJIT AQUA EXTRACTION PLANT |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 415 |

| Capacity | 100 TPD |

| Usage/Application | Extract |

| Machine Type | Aqua Extraction |

| Others: | |

| Brand | MECH O TECH |

| Country of Origin | Made in India |

| I Deal In | New Only |

| Installation Services | Yes |

Agarwood Absolute Solvent Extraction Plant 100 TPD

Brand:

Others

Price ₹

50,00,000.00

| General Details: | |

| Model | Agarwood Absolute Solvent Extraction Plant 100 TPD |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 220 / 415 / 380 |

| Capacity | 100 TPD |

| Usage/Application | AGARWOOD ABSOLUTE |

| Machine Type | TURN KEY |

| Power Source | ELECTRICAL / WOOD |

| Design Type | TAILORE MADE |

| Others: | |

| Brand | MECH O TECH |

| Installation Services | Yes |

Andrographis Paniculata Extraction Plant Manufacturers 100 TPD

Brand:

Others

Price ₹

25,00,000.00

| General Details: | |

| Model | Andrographis Paniculata Extraction Plant Manufacturers 100 TPD |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Capacity | 100 TPD |

| Others: | |

| Brand | mechotech llp |

| Installation Services | Yes |

Red Chilly Powder Extraction Plant Manufacturers

Brand:

Others

Price ₹

1,00,00,000.00

| General Details: | |

| Model | Red Chilly Powder Extraction Plant Manufacturers |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Capacity | 100 TPD |

| Others: | |

| I Deal In | New Only |

| Brand | Mechotechllp |

| Country of Origin | Made in India |

| Installation Services | Yes |

| Country of Origin | Made in India |

| Business Type | Manufacturer, Supplier |

Shilajit Extract Plant Manufacturers

Brand:

Others

Price ₹

35,00,000.00

| General Details: | |

| Model | Shilajit Extract Plant Manufacturers |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Capacity | 100 TPD |

| Others: | |

| Brand | Mechotech |

| Country of Origin | Made in India |

| Installation Services | Yes |

Garlic Oleoresin Extraction Plant Manufacturing plant, Capacity: 100 TPD

Brand:

Others

Price ₹

52,00,000.00

| General Details: | |

| Model | Garlic Oleoresin Extraction Plant Manufacturing plant, Capacity: 100 TPD |

| Material | Stainless Steel |

| Capacity | 100 TPD |

| Usage/Application | Food Flavour |

| Others: | |

| Color | Silver |

| Form | Liquid |

| Installation Services | Yes |

| Packaging Size | 5 kg |

| Shelf Life | 24 Months |

| Solubility | Garlic Soluble |

Mustard Oleoresin Extraction Plant

Brand:

Others

Price ₹

50,00,000.00

| General Details: | |

| Model | Mustard Oleoresin Extraction Plant |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 220 V |

| Capacity | 100 TPD |

| Usage/Application | Industrial |

| Machine Type | Mustard Oleoresin Extraction |

| Others: | |

| Frequency | 50 Hz |

Capsaicin Oleoresin Extraction Plant

Brand:

Others

Price ₹

50,00,000.00

| General Details: | |

| Model | Capsaicin Oleoresin Extraction Plant |

| Material | Stainless Steel |

| Automation Grade | Automatic |

| Voltage | 120V |

| Capacity | 100 TPD |

| Usage/Application | Industrial Use |

| Others: | |

| Country of Origin | Made in India |

| Frequency | 50Hz |

| Phase | Single |

Spices Oleoresin Extraction Plant

Brand:

Others

Price ₹

50,00,000.00

| General Details: | |

| Model | Spices Oleoresin Extraction Plant |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 220 V |

| Capacity | 100 TPD |

| Usage/Application | Industrial |

| Machine Type | Oleoresin Extraction Plant |

| Power Source | Electric |

| Others: | |

| Frequency | 50 Hz |

| I Deal In | New Only |

Oleoresin Extraction Plant Manufacturers

Brand:

Others

Price ₹

50,00,000.00

| General Details: | |

| Model | Oleoresin Extraction Plant Manufacturers |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 220 V |

| Capacity | 100 TPD |

| Usage/Application | Industrial |

| Machine Type | Oleoresin Extraction Plant |

| Power Source | Electric |

| Others: | |

| Frequency | 50 Hz |

| I Deal In | New Only |

Cardmom Oleoresin Extraction Plant

Brand:

Others

Price ₹

50,00,000.00

| General Details: | |

| Model | Cardmom Oleoresin Extraction Plant |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 220 V |

| Capacity | 100 TPD |

| Usage/Application | Industrial |

| Machine Type | Cardmom Oleoresin Extraction |

| Power Source | Electric Source |

| Others: | |

| Frequency | 50 Hz |

| I Deal In | New Only |

Cumin Oleoresin Extraction Plant

Brand:

Others

Price ₹

50,00,000.00

| General Details: | |

| Model | Cumin Oleoresin Extraction Plant |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 220 V |

| Capacity | 100 TPD |

| Usage/Application | Industrial |

| Machine Type | Cumin Oleoresin Extraction |

| Power Source | Electric |

| Others: | |

| Frequency | 50 Hz |

| I Deal In | New Only |

Coriander Oleoresin Extraction Plant 100 TPD

Brand:

Others

Price ₹

50,00,000.00

| General Details: | |

| Model | Coriander Oleoresin Extraction Plant 100 TPD |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 220 V |

| Capacity | 100 TPD |

| Usage/Application | Industrial |

| Machine Type | Coriander Oleoresin Extraction |

| Power Source | Electric |

| Others: | |

| Frequency | 50 Hz |

| I Deal In | New Only |

Capsicum Oleoresin Extraction Plant

Brand:

Others

Price ₹

50,00,000.00

| General Details: | |

| Model | Capsicum Oleoresin Extraction Plant |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 120V |

| Capacity | 100 TPD |

| Usage/Application | Industrial Use |

| Power Source | Electric |

| Others: | |

| Frequency | 50 Hz |

| I Deal In | New Only |

Lutein Extraction Plant Manufacturers In India

Brand:

Others

Price ₹

10,00,000.00

| General Details: | |

| Model | Lutein Extraction Plant Manufacturers In India |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 220 V |

| Capacity | 100 TPD |

| Usage/Application | Industrial |

| Machine Type | Lutein Extraction Plant |

| Power Source | Electric |

| Others: | |

| Frequency | 60 Hz |

| I Deal In | New Only |

| Phase | Single Phase |

Marigold Solvent Extraction Plant Manufacturers In India

Brand:

Others

Price ₹

10,00,000.00

| General Details: | |

| Model | Marigold Solvent Extraction Plant Manufacturers In India |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 240 V |

| Capacity | 500 TPD |

| Usage/Application | Industrial |

| Machine Type | Solvent Extraction |

| Power Source | Electric |

| Others: | |

| Frequency | 60 Hz |

Marigold Extraction Plant Manufacturers In Hyderabad

Brand:

Others

Price ₹

10,00,000.00

| General Details: | |

| Model | Marigold Extraction Plant Manufacturers In Hyderabad |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 240 V |

| Capacity | 500 TPD |

| Usage/Application | Industrial |

| Machine Type | Extraction Plant |

| Power Source | Electric |

Marigold Solvent Extraction Palnt 100 TPD

Brand:

Others

Price ₹

10,00,000.00

| General Details: | |

| Model | Marigold Solvent Extraction Palnt 100 TPD |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 220 V |

| Capacity | 100 TPD |

| Usage/Application | Industrial |

| Machine Type | Solvent Extraction |

| Power Source | Electric |

| Others: | |

| Frequency | 50Hz |

| I Deal In | New Only |

| Phase | Single Phase |

Marigold Dye Extraction Equipment 100 TPD

Brand:

Others

Price ₹

10,00,000.00

| General Details: | |

| Model | Marigold Dye Extraction Equipment 100 TPD |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 220 V |

| Capacity | 100 TPD |

| Usage/Application | Industrial |

| Machine Type | Dye Extraction |

| Power Source | Electric |

| Others: | |

| Frequency | 50 Hz |

| I Deal In | New Only |

| Phase | Single Phase |

Marigold Pigment Extraction Plant

Brand:

Others

Price ₹

10,00,000.00

| General Details: | |

| Model | Marigold Pigment Extraction Plant |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 220V |

| Capacity | 100 TPD |

| Usage/Application | Industrial |

| Machine Type | Pigment Extraction |

| Power Source | Electric |

| Others: | |

| Frequency | 50 Hz |

| I Deal In | New Only |

Marigold Flower Extraction Plant

Brand:

Others

Price ₹

10,00,000.00

| General Details: | |

| Model | Marigold Flower Extraction Plant |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 220 V |

| Capacity | 100 TPD |

| Usage/Application | Industrial |

| Machine Type | Flower Extraction |

| Power Source | Electric |

| Others: | |

| Frequency | 50 Hz |

| I Deal In | New Only |

Shilajit Solvent Extraction Plant, Capacity: 100 TPD

Brand:

Others

Price ₹

15,00,000.00

| General Details: | |

| Model | Shilajit Solvent Extraction Plant, Capacity: 100 TPD |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Capacity | 100 TPD |

| Usage/Application | Yes |

| Machine Type | Yes |

| Power Source | Yes |

| Others: | |

| Brand | Yes |

| Installation Services | Yes |

Industrial Solvent Extraction Plant, Capacity: 100 TPD

Brand:

Others

Price ₹

15,00,000.00

| General Details: | |

| Model | Industrial Solvent Extraction Plant, Capacity: 100 TPD |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Capacity | 100 TPD |

| Usage/Application | Yes |

| Machine Type | Yes |

| Power Source | Yes |

| Design Type | Yes |

| Others: | |

| Brand | Yes |

| Installation Services | Yes |

Vanilla Seeds & Berries Extraction Plants, Capacity: 1

Brand:

Others

Price ₹

50,00,000.00

| General Details: | |

| Model | Vanilla Seeds & Berries Extraction Plants, Capacity: 1 |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | yes |

| Driven Type | Electrical |

| Motor | yes |

| Capacity | 1 |

| Usage/Application | yes |

| Machine Type | Yes |

| Power Source | yes |

| Design Type | yes |

| Thickness Of Flakes | yes |

| Pressure | yes |

| Temperature Range | yes |

| Others: | |

| Brand | Mechotechllp |

| Installation Services | Yes |

Nicotine Sulphate Extraction Plant

Brand:

Others

Price ₹

1,00,00,000.00

| General Details: | |

| Model | NICOTINE SULPHATE EXTRACTION PLANT |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 415 |

| Capacity | 100 TPD |

| Usage/Application | Tobacco extraction |

| Machine Type | Solvent Extraction |

| Power Source | Electricity |

| Design Type | Turnkey |

| Others: | |

| Brand | MECH O TECH |

| Country of Origin | Made in India |

| Frequency | 50 |

| Installation Services | Yes |

| Phase | 3 |

Tropane Alkaloids Extraction Plants

Brand:

Others

Price ₹

25,00,000.00

| General Details: | |

| Model | Solvent extraction plant |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 415 |

| Driven Type | Electrical |

| Motor | yes |

| Capacity | Customization |

| Usage/Application | Herbal Extraction |

| Machine Type | Yes |

| Power Source | Electrical |

| Design Type | yes |

| Thickness Of Flakes | yes |

| Pressure | yes |

| Temperature Range | yes |

| Others: | |

| Brand | mechotech |

| Installation Services | Yes |

Ergot Alkaloids Extraction Plants

Brand:

Others

Price ₹

35,00,000.00

| General Details: | |

| Model | Solvent extraction plant |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 415 |

| Driven Type | Electrical |

| Capacity | Customization |

| Usage/Application | Herbal Extraction |

| Machine Type | Yes |

| Power Source | Electrical |

| Design Type | yes |

| Thickness Of Flakes | yes |

| Pressure | yes |

| Temperature Range | yes |

| Others: | |

| Brand | Mechotechhlp |

Pyridine (Nicotine) Alkaloids Extraction Plants

Brand:

Others

Price ₹

50,00,000.00

| General Details: | |

| Model | Solvent extraction plant |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 415 |

| Driven Type | Electrical |

| Capacity | Customization |

| Usage/Application | Herbal Extraction |

| Machine Type | Yes |

| Power Source | Electrical |

| Others: | |

| Brand | Mechotechllp |

Pyrrolizidine Alkaloids Extraction Plants

Brand:

Others

Price ₹

35,00,000.00

| General Details: | |

| Model | Solvent extraction plant |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 415 |

| Driven Type | Electrical |

| Motor | yes |

| Capacity | Customization |

| Usage/Application | Herbal Extraction |

| Machine Type | Yes |

| Power Source | Electrical |

| Design Type | yes |

| Thickness Of Flakes | yes |

| Pressure | yes |

| Temperature Range | yes |

| Others: | |

| Brand | Mechotechllp |

Quinoline Alkaloids Extraction Plants

Brand:

Others

Price ₹

50,00,000.00

| General Details: | |

| Model | Solvent extraction plant |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 415 |

| Driven Type | Electrical |

| Motor | yes |

| Capacity | Customization |

| Usage/Application | Herbal Extraction |

| Machine Type | yes |

| Power Source | Electrical |

| Design Type | yes |

| Thickness Of Flakes | yes |

| Pressure | yes |

| Temperature Range | yes |

| Others: | |

| Brand | mechotechllp |

Vinblastine Alkaloids Extraction Plants

Brand:

Others

Price ₹

45,00,000.00

| General Details: | |

| Model | Solvent extraction plant |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 415 |

| Driven Type | Electrical |

| Motor | yes |

| Capacity | Customization |

| Usage/Application | Herbal Extraction |

| Machine Type | yes |

| Power Source | Electrical |

| Design Type | yes |

| Thickness Of Flakes | yes |

| Pressure | yes |

| Temperature Range | yes |

| Others: | |

| Brand | Mechotechllp |

Piperidine Alkaloids Extraction Plants

Brand:

Others

Price ₹

25,00,000.00

| General Details: | |

| Model | Solvent extraction plant |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 415 |

| Driven Type | Electrical |

| Capacity | Customization |

| Usage/Application | Herbal Extraction |

| Machine Type | Yes |

| Power Source | Electrical |

| Design Type | yes |

| Thickness Of Flakes | yes |

| Pressure | yes |

| Temperature Range | yes |

| Others: | |

| Brand | Mechotechllp |

Peanut Protein Extraction Plant, Capacity: 1

Brand:

Others

Price ₹

15,00,000.00

| General Details: | |

| Model | Peanut Protein Extraction Plant, Capacity: 1 |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 240V |

| Driven Type | Electrical |

| Motor | yes |

| Capacity | 1 |

| Usage/Application | yes |

| Machine Type | yes |

| Power Source | Electric |

| Design Type | yes |

| Thickness Of Flakes | yes |

| Pressure | yes |

| Temperature Range | yes |

| Others: | |

| Brand | MECHOTECH LLP |

Soya Beans Protein Extraction Plant, Capacity: 1

Brand:

Others

Price ₹

25,00,000.00

| General Details: | |

| Model | Soya Beans Protein Extraction Plant, Capacity: 1 |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Capacity | 1 |

| Usage/Application | yes |

| Machine Type | yes |

| Others: | |

| Brand | mechotechllp |

Brahmi extraction plant manufacturing

Brand:

Others

Price ₹

90,00,000.00

| General Details: | |

| Model | Brahmi extraction plant manufacturing |

| Material | Stainless Steel |

| Automation Grade | Manual |

| Voltage | 240V |

| Driven Type | yes |

| Motor | yes |

| Capacity | Customization |

| Usage/Application | Herbal Extraction |

| Machine Type | Solvent Extraction |

| Power Source | Electrical |

| Design Type | yes |

| Thickness Of Flakes | yes |

| Pressure | yes |

| Temperature Range | yes |

| Others: | |

| Brand | MECHOTECH LLP |

| Installation Services | Yes |

Gymnema Extraction Plant, Capacity: 100 TPD

Brand:

Others

Price ₹

15,00,000.00

| General Details: | |

| Model | Gymnema Extraction Plant, Capacity: 100 TPD |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Capacity | 100 TPD |

| Usage/Application | Yes |

| Machine Type | Yes |

| Power Source | Yes |

| Design Type | Yes |

| Others: | |

| Brand | Yes |

| Installation Services | Yes |

Australian Sandal Wood Absolute Extraction Plants, Capacity: 1

Brand:

Others

Price ₹

35,00,000.00

| General Details: | |

| Model | Australian Sandal Wood Absolute Extraction Plants, Capacity: 1 |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Capacity | 1 |

| Usage/Application | Yes |

| Others: | |

| Brand | Mechotechllp |

Agarwood /Oud Wood Absolute Extraction Plants, Capacity: 1

Brand:

Others

Price ₹

25,00,000.00

| General Details: | |

| Model | Agarwood /Oud Wood Absolute Extraction Plants, Capacity: 1 |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | yes |

| Capacity | 1 |

| Usage/Application | Yes |

| Machine Type | Manual |

| Power Source | yes |

| Design Type | yes |

| Others: | |

| Brand | Mechotechllp |

Oak Moss (Moss / Lichen) Wood Absolute Extraction Plants, Capacity: 1

Brand:

Others

Price ₹

35,00,000.00

| General Details: | |

| Model | Oak Moss (Moss / Lichen) Wood Absolute Extraction Plants, Capacity: 1 |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Capacity | 1 |

| Usage/Application | Yes |

| Machine Type | yes |

| Others: | |

| Brand | Mechotechllp |

Indian sandal Wood Absolute Extraction Plants, Capacity: 1

Brand:

Others

Price ₹

25,00,000.00

| General Details: | |

| Model | Indian sandal Wood Absolute Extraction Plants, Capacity: 1 |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Capacity | 1 |

| Usage/Application | yes |

| Machine Type | yes |

| Others: | |

| Brand | Mechotechllp |

Curcumin Solvent Extraction Plant, Capacity: 100 TPD

Brand:

Others

Price ₹

10,00,000.00

| General Details: | |

| Model | Curcumin Solvent Extraction Plant, Capacity: 100 TPD |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Capacity | 100 TPD |

| Usage/Application | Yes |

| Machine Type | Yes |

| Power Source | Yes |

| Design Type | Yes |

| Others: | |

| Brand | Yes |

| Installation Services | Yes |

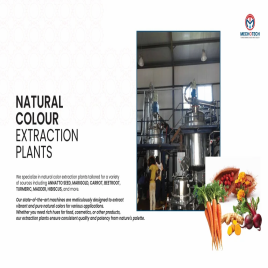

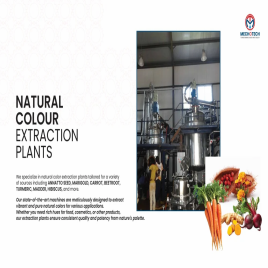

Skins - Red Onions Natural color extraction plant, Capacity: 10TPD

Brand:

Others

Price ₹

25,00,000.00

| General Details: | |

| Model | Skins - Red Onions Natural color extraction plant, Capacity: 10TPD |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Capacity | 10TPD |

| Usage/Application | Natural Color Extraction plant |

| Others: | |

| Brand | Mech O tech |

| Country of Origin | Made in India |

| Installation Services | Yes |

Dogwood /Mulberries / Elderberries /Blueberries Natural color extraction plant

Brand:

Others

Price ₹

35,00,000.00

| General Details: | |

| Model | Dogwood /Mulberries / Elderberries /Blueberries Natural color extraction plant |

| Material | Stainless Steel |

| Capacity | 10tpd |

| Usage/Application | natural color extraction plant |

| Others: | |

| Brand | Mech O Tech |

| Country of Origin | Made in India |

| Installation Services | Yes |

Flower - Hyacinth / Cornflower Natural color extraction plant, Capacity: 10TPD

Brand:

Others

Price ₹

35,00,000.00

| General Details: | |

| Model | Flower - Hyacinth / Cornflower Natural color extraction plant, Capacity: 10TPD |

| Material | Stainless Steel |

| Capacity | 10TPD |

| Usage/Application | Natural Color Extraction plant |

| Others: | |

| Brand | Mech O tech |

| Country of Origin | Made in India |

| Installation Services | Yes |

Foliage - Indigo Natural color extraction plant, Capacity: 10tpd

Brand:

Others

Price ₹

25,00,000.00

| General Details: | |

| Model | Foliage - Indigo Natural color extraction plant, Capacity: 10tpd |

| Material | Stainless Steel |

| Capacity | 10tpd |

| Usage/Application | Natural color Extraction Plant |

| Others: | |

| Brand | Mech O tech |

| Country of Origin | Made in India |

| Installation Services | Yes |

Plant - Larkspur / Dyer''s Broom Natural color Extraction plant, Capacity: 10tpd

Brand:

Others

Price ₹

40,00,000.00

| General Details: | |

| Model | Plant - Larkspur / Dyer''s Broom Natural color Extraction plant, Capacity: 10tpd |

| Material | Stainless Steel |

| Capacity | 10tpd |

| Usage/Application | Natural Color Extraction Plant |

| Others: | |

| Brand | Mech O Tech |

| Country of Origin | Made in India |

| Installation Services | Yes |

Chirata Extraction plant manufacturer

Brand:

Others

Price ₹

50,00,000.00

| General Details: | |

| Model | Chirata Extract plant manufacturer |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 240V |

| Driven Type | Electrical |

| Motor | yes |

| Capacity | Customization |

| Usage/Application | Herbal Extraction |

| Machine Type | Solvent Extraction |

| Power Source | Electric |

| Design Type | yes |

| Thickness Of Flakes | yes |

| Pressure | yes |

| Temperature Range | yes |

| Others: | |

| Brand | MECHOTECH LLP |

| Installation Services | Yes |

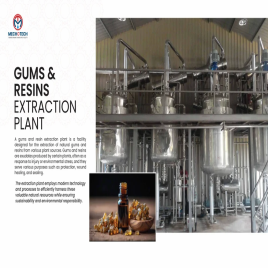

Styrax Benzoin Absolute Gum & Resin Extraction Plant, Capacity: 1

Brand:

Others

Price ₹

50,00,000.00

| General Details: | |

| Model | Styrax Benzoin Absolute Gum & Resin Extraction Plant, Capacity: 1 |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 240V |

| Driven Type | Electrical |

| Motor | yes |

| Capacity | 1 |

| Usage/Application | yes |

| Machine Type | yes |

| Power Source | Electric |

| Design Type | yes |

| Thickness Of Flakes | yes |

| Pressure | yes |

| Temperature Range | yes |

| Others: | |

| Brand | mechotechllp |

Frankinscence / Olibanum Gum & Resin Extraction Plant, Capacity: 1

Brand:

Others

Price ₹

20,00,000.00

| General Details: | |

| Model | Frankinscence / Olibanum Gum & Resin Extraction Plant, Capacity: 1 |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Capacity | 1 |

| Usage/Application | yes |

| Machine Type | yes |

| Others: | |

| Brand | Mechotechllp |

Myrrh / Opoponax Gum & Resin Extraction Plant, Capacity: 1

Brand:

Others

Price ₹

50,00,000.00

| General Details: | |

| Model | Myrrh / Opoponax Gum & Resin Extraction Plant, Capacity: 1 |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 240V |

| Driven Type | Electrical |

| Motor | yes |

| Capacity | 1 |

| Usage/Application | yes |

| Machine Type | yes |

| Power Source | Electric |

| Design Type | yes |

| Thickness Of Flakes | yes |

| Pressure | yes |

| Temperature Range | yes |

| Others: | |

| Brand | Mechotechllp |

Airvalanta Extraction Plant Manufacturers, Capacity: 100 TPD

Brand:

Others

Price ₹

20,00,000.00

| General Details: | |

| Model | Airvalanta Extraction Plant Manufacturers, Capacity: 100 TPD |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Capacity | 100 TPD |

| Others: | |

| Brand | Mechotech |

| Country of Origin | Made in India |

| Installation Services | Yes |

Annanthamool Extraction Plant Manufacturers, Capacity: 100 TPD

Brand:

Others

Price ₹

8,00,000.00

| General Details: | |

| Model | Annanthamool Extraction Plant Manufacturers, Capacity: 100 TPD |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 240V |

| Driven Type | Electrical |

| Motor | yes |

| Capacity | 100 TPD |

| Usage/Application | Herbal Extraction |

| Machine Type | Solvent Extraction |

| Power Source | Electric |

| Design Type | yes |

| Thickness Of Flakes | yes |

| Pressure | yes |

| Temperature Range | yes |

| Others: | |

| Brand | Mechotech |

| Country of Origin | Made in India |

| Installation Services | Yes |

Black Cumin extraction plant manufacturing

Brand:

Others

Price ₹

60,00,000.00

| General Details: | |

| Model | Black Cumin extraction plant manufacturing |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 240V |

| Driven Type | Electrical |

| Motor | yes |

| Capacity | Customization |

| Usage/Application | Herbal Extraction |

| Machine Type | Solvent Extraction |

| Power Source | Electric |

| Design Type | yes |

| Thickness Of Flakes | yes |

| Pressure | yes |

| Temperature Range | yes |

| Others: | |

| Installation Services | Yes |

| Brand | MECHOTECH LLP |

| Country of Origin | Made in India |

Annato Seed Extraction Plant Manufacturers, Capacity: 100 TPD

Brand:

Others

Price ₹

5,00,000.00

| General Details: | |

| Model | Annato Seed Extraction Plant Manufacturers, Capacity: 100 TPD |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 240V |

| Driven Type | Electrical |

| Motor | yes |

| Capacity | 100 TPD |

| Usage/Application | Herbal Extraction |

| Machine Type | Solvent Extraction |

| Power Source | Electric |

| Design Type | yes |

| Thickness Of Flakes | yes |

| Pressure | yes |

| Temperature Range | yes |

| Others: | |

| Brand | Mechotech |

| Country of Origin | Made in India |

| Installation Services | Yes |

Ashwagandha root Extraction Plant, Capacity: 100 TPD

Brand:

Others

Price ₹

15,00,000.00

| General Details: | |

| Model | Ashwagandha root Extraction Plant, Capacity: 100 TPD |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 240V |

| Driven Type | Electrical |

| Motor | yes |

| Capacity | 100 TPD |

| Usage/Application | Yes |

| Machine Type | Yes |

| Power Source | Yes |

| Design Type | Yes |

| Thickness Of Flakes | yes |

| Pressure | yes |

| Temperature Range | yes |

| Others: | |

| Brand | Yes |

| Installation Services | Yes |

Curcumin Extraction Plant, Capacity: 100 TPD

Brand:

Others

Price ₹

1,20,00,000.00

| General Details: | |

| Model | Curcumin Extraction Plant, Capacity: 100 TPD |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 415V |

| Capacity | 100 TPD |

| Usage/Application | Curcumin / Turmeric Extraction |

| Machine Type | Turn Key Project |

| Power Source | Electrical |

| Others: | |

| Brand | Mech O Tech |

| Country of Origin | Made in India |

| Frequency | 60Hz |

| Installation Services | Yes |

| Phase | Three |

Curcumin Extraction Plant Cost In India, Capacity: 30 TPD

Brand:

Others

Price ₹

50,00,000.00

| General Details: | |

| Model | Curcumin Extraction Plant Cost In India, Capacity: 30 TPD |

| Material | SS 316 / SS 304 |

| Automation Grade | SEMI AUTOMATIC |

| Voltage | 220 / 415 V |

| Capacity | 30 TPD |

| Usage/Application | CURCUMIN EXTRACTION |

| Power Source | ELECTRICAL |

| Others: | |

| Country of Origin | Made in India |

| Frequency | 50 / 60 HZ |

| I Deal In | New and Second Hand |

| Installation Services | Yes |

| Phase | 3 PHASE |

Curcumin Solvent Extraction unit Manufacturer in orissa, Capacity: 100 TPD

Brand:

Others

Price ₹

10,00,000.00

| General Details: | |

| Model | Curcumin Solvent Extraction unit Manufacturer in orissa, Capacity: 100 TPD |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 220 / 415 V |

| Capacity | 100 TPD |

| Usage/Application | TURMERIC / CURCUMIN EXTRACT |

| Power Source | ELECTRICAL |

| Others: | |

| Brand | MECH O TECH |

| Installation Services | Yes |

Bhringraj extraction plant manufacturing

Brand:

Others

Price ₹

50,00,000.00

| General Details: | |

| Model | Bhringraj extraction plant manufacturing |

| Material | Stainless Steel |

| Automation Grade | Manual |

| Voltage | 240V |

| Driven Type | yes |

| Motor | yes |

| Capacity | Customization |

| Usage/Application | Herbal Extraction |

| Machine Type | Solvent Extraction |

| Power Source | Electric |

| Design Type | yes |

| Thickness Of Flakes | yes |

| Pressure | yes |

| Temperature Range | yes |

| Others: | |

| Brand | MECHOTECH LLP |

| Installation Services | Yes |

Alkaloids extraction plant, Capacity: 100 TPD

Brand:

Others

Price ₹

10,00,000.00

| General Details: | |

| Model | Alkaloids extraction plant, Capacity: 100 TPD |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Capacity | 100 TPD |

| Usage/Application | Yes |

| Machine Type | Yes |

| Power Source | Yes |

| Design Type | Yes |

| Others: | |

| Brand | Yes |

| Installation Services | Yes |

Essential Oil Solvent Extraction Unit, Capacity: 100 TPD

Brand:

Others

Price ₹

15,00,000.00

| General Details: | |

| Model | Essential Oil Solvent Extraction Unit, Capacity: 100 TPD |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | Yes |

| Capacity | 100 TPD |

| Usage/Application | Yes |

| Machine Type | Yes |

| Power Source | Yes |

| Design Type | Yes |

| Others: | |

| Brand | Yes |

| Installation Services | Yes |

Leaves - Sumac Natural color Extraction plant, Capacity: 1

Brand:

Others

Price ₹

25,00,000.00

| General Details: | |

| Model | Leaves - Sumac Natural color Extraction plant, Capacity: 1 |

| Material | 1 |

| Automation Grade | Semi Automatic |

| Capacity | 1 |

| Usage/Application | yes |

| Machine Type | manal |

| Power Source | yes |

| Others: | |

| Brand | Mechotechllp |

| Installation Services | Yes |

Roots - Iris Natural color Extraction plant, Capacity: 1

Brand:

Others

Price ₹

15,00,000.00

| General Details: | |

| Model | Roots - Iris Natural color Extraction plant, Capacity: 1 |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Capacity | 1 |

| Usage/Application | yes |

| Machine Type | yes |

| Others: | |

| Brand | Mechotechllp |

Galls - Oak Galls Natural color extraction plant, Capacity: 1

Brand:

Others

Price ₹

25,00,000.00

| General Details: | |

| Model | Galls - Oak Galls Natural color extraction plant, Capacity: 1 |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Capacity | 1 |

| Usage/Application | yes |

| Others: | |

| Brand | Mechotechllp |

Vegatables - Balck Carrot / Black Currant Natural color Extraction plant

Brand:

Others

Price ₹

7,50,000.00

| General Details: | |

| Model | Vegatables - Balck Carrot / Black Currant Natural color Extraction plant |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | yes |

| Driven Type | Electrical |

| Motor | yes |

| Capacity | 1 |

| Usage/Application | yes |

| Machine Type | Yes |

| Power Source | Electrical |

| Design Type | yes |

| Thickness Of Flakes | yes |

| Pressure | yes |

| Temperature Range | yes |

| Others: | |

| Brand | Mechotechllp |

| Installation Services | Yes |

Grains - Black Rice Natural color Extraction plant, Capacity: 1

Brand:

Others

Price ₹

15,00,000.00

| General Details: | |

| Model | Grains - Black Rice Natural color Extraction plant, Capacity: 1 |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Capacity | 1 |

| Usage/Application | yes |

| Machine Type | yes |

| Others: | |

| Brand | Mechotechllp |

Hulls -Walnut Natural color Extraction plant, Capacity: 1

Brand:

Others

Price ₹

20,00,000.00

| General Details: | |

| Model | Hulls -Walnut Natural color Extraction plant, Capacity: 1 |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Capacity | 1 |

| Usage/Application | yes |

| Machine Type | yes |

| Others: | |

| Brand | Mechotechllp |

Woody Stems - Ivy Brown Color Extraction Plant, Capacity: 10TPD

Brand:

Others

Price ₹

1,00,00,000.00

| General Details: | |

| Model | Woody Stems - Ivy Brown Color Extraction Plant, Capacity: 10TPD |

| Material | Stainless Steel |

| Capacity | 10TPD |

| Usage/Application | Natural Color Extraction Plant |

| Others: | |

| Brand | Mech O Tech |

| Installation Services | Yes |

Shoots - Golden Rod Brown Color Extraction Plant, Capacity: 10TPD

Brand:

Others

Price ₹

1,00,00,000.00

| General Details: | |

| Model | Shoots - Golden Rod Brown Color Extraction Plant, Capacity: 10TPD |

| Material | Stainless Steel |

| Capacity | 10TPD |

| Usage/Application | Natural Color Extraction Plant |

| Others: | |

| Brand | Mech o Tech |

| Country of Origin | Made in India |

| Installation Services | Yes |

Oak Bark / Birch Brown Color Extraction Plant, Capacity: 10TPD

Brand:

Others

Price ₹

1,00,00,000.00

| General Details: | |

| Model | Oak Bark / Birch Brown Color Extraction Plant, Capacity: 10TPD |

| Material | Stainless Steel |

| Capacity | 10TPD |

| Usage/Application | Natural Color Extraction Plant |

| Others: | |

| Brand | Mech o Tech |

| Country of Origin | Made in India |

| Installation Services | Yes |

Hulls -Walnut Brown Color Extraction Plant, Capacity: 10TPD

Brand:

Others

Price ₹

1,00,00,000.00

| General Details: | |

| Model | Hulls -Walnut Brown Color Extraction Plant, Capacity: 10TPD |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Capacity | 10TPD |

| Usage/Application | Natural Color Extraction Plant |

| Others: | |

| Brand | Mech O Tech |

| Country of Origin | Made in India |

| Installation Services | Yes |

Roots - Dandelion Brown Color Extraction Plant, Capacity: 10TPD

Brand:

Others

Price ₹

1,00,00,000.00

| General Details: | |

| Model | Roots - Dandelion Brown Color Extraction Plant, Capacity: 10TPD |

| Material | Stainless Steel |

| Capacity | 10TPD |

| Usage/Application | Natural Color Extraction Plant |

| Others: | |

| Brand | Mech O Tech |

| Country of Origin | Made in India |

| Installation Services | Yes |

Grinds - Coffee Brown Color Extraction Plant, Capacity: 10TPD

Brand:

Others

Price ₹

1,00,00,000.00

| General Details: | |

| Model | Grinds - Coffee Brown Color Extraction Plant, Capacity: 10TPD |

| Material | Stainless Steel |

| Capacity | 10TPD |

| Usage/Application | Natural Color Extraction Plant |

| Others: | |

| Brand | Mech O Tech |

| Country of Origin | Made in India |

| Installation Services | Yes |

Gaint Coreopsis / BarBerry Orange Color Extraction Plant, Capacity: 10TPD

Brand:

Others

Price ₹

1,00,00,000.00

| General Details: | |

| Model | Gaint Coreopsis / BarBerry Orange Color Extraction Plant, Capacity: 10TPD |

| Material | Stainless Steel |

| Capacity | 10TPD |

| Usage/Application | Natural Color Extraction Plant |

| Others: | |

| Brand | Mech O Tech |

| Country of Origin | Made in India |

| Installation Services | Yes |

Eucalyptus Leaves Orange Color Extraction Plant, Capacity: 10TPD

Brand:

Others

Price ₹

1,00,00,000.00

| General Details: | |

| Model | Eucalyptus Leaves Orange Color Extraction Plant, Capacity: 10TPD |

| Material | Stainless Steel |

| Capacity | 10TPD |

| Usage/Application | Natural Color Extraction Plant |

| Others: | |

| Brand | Mech O Tech |

| Country of Origin | Made in India |

| Installation Services | Yes |

Flaxseed Extraction Plant, Capacity: 100 TPD

Brand:

Others

Price ₹

10,00,000.00

| General Details: | |

| Model | Flaxseed Extraction Plant, Capacity: 100 TPD |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Capacity | 100 TPD |

| Usage/Application | Yes |

| Machine Type | Yes |

| Power Source | Yes |

| Design Type | Yes |

| Others: | |

| Brand | Yes |

| Installation Services | Yes |

Milk Thistle Seed plant manufacturers in hyderabad

Brand:

Others

Price ₹

15,00,000.00

| General Details: | |

| Model | Milk Thistle Seed plant manufacturers in hyderabad |

| Material | Natural |

| Automation Grade | Semi Automatic |

| Capacity | 100 TPD |

| Others: | |

| 1 Ton | 2500000 |

| Brand | Mechotechllp |

| Country of Origin | Made in India |

| Installation Services | Yes |

Boswellia Serrata Extract plan manufacturers

Brand:

Others

Price ₹

50,00,000.00

| General Details: | |

| Model | Boswellia Serrata Extract plan manufacturers |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Capacity | 100 TPD |

| Others: | |

| Brand | MECHOTECH LLP |

| Country of Origin | Made in India |

| Installation Services | Yes |

Boswelli serrata extraction plant manufacturing

Brand:

Others

Price ₹

50,00,000.00

| General Details: | |

| Model | Boswelli serrata extraction plant manufacturing |

| Material | Stainless Steel |

| Automation Grade | Manual |

| Others: | |

| Brand | MECHOTECH LLP |

| Installation Services | Yes |

Cassia Extraction Plant Manufacturing

Brand:

Others

Price ₹

50,00,000.00

| General Details: | |

| Model | Cassia Extraction Plant Manufacturing |

| Material | Stainless Steel |

| Automation Grade | Manual |

| Voltage | 415 |

| Driven Type | Electrical |

| Motor | yes |

| Capacity | yes |

| Usage/Application | Herbal Extraction |

| Machine Type | Yes |

| Power Source | Electrical |

| Design Type | yes |

| Thickness Of Flakes | yes |

| Pressure | yes |

| Temperature Range | yes |

| Others: | |

| Brand | mechotech llp |

| Installation Services | Yes |

Bacopa Monneri extraction plant manufacturing

Brand:

Others

Price ₹

7,00,000.00

| General Details: | |

| Model | Bacopa Monneri extraction plant manufacturing |

| Others: | |

| Business Type | Manufacturer, Supplier |

| Condition | Brand New |

| Country of Origin | Made in India |

| Features | Lower energy consumption |

| I Deal In | New Only |

| Minimum Quantity Order | 1 Unit |

| Usage/Application | Bacosides extraction |

Beheda extraction plant manufacturing

Brand:

Others

Price ₹

30,00,000.00

| General Details: | |

| Model | Beheda extraction plant manufacturing |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 240V |

| Driven Type | Electrical |

| Motor | yes |

| Capacity | Customization |

| Usage/Application | Herbal Extraction |

| Machine Type | Solvent Extraction |

| Power Source | Electric |

| Design Type | Yes |

| Thickness Of Flakes | yes |

| Pressure | yes |

| Temperature Range | yes |

| Others: | |

| Country of Origin | Made in India |

| Brand | MECHOTECH LLP |

Centella Asiatica Extract plant manufacturing

Brand:

Others

Price ₹

70,00,000.00

| General Details: | |

| Model | Centella Asiatica Extract plant manufacturing |

| Material | Stainless Steel |

| Automation Grade | Manual |

| Voltage | 240V |

| Driven Type | yes |

| Motor | yes |

| Capacity | Customization |

| Usage/Application | Herbal Extraction |

| Machine Type | Solvent Extraction |

| Power Source | Electric |

| Design Type | yes |

| Thickness Of Flakes | yes |

| Pressure | yes |

| Temperature Range | yes |

| Others: | |

| Installation Services | Yes |

Oleoresin Extraction Equipment , Capacity : 100 TPD

Brand:

Others

Price ₹

7,00,000.00

| General Details: | |

| Model | Oleoresin Extraction Equipment , Capacity : 100 TPD |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 220 V |

| Capacity | 100 TPD |

| Usage/Application | Industrial |

| Machine Type | Extraction Equipment |

| Power Source | Electric |

| Others: | |

| Frequency | 50 Hz |

| I Deal In | New Only |

| Phase | Single Phase |

Herbal solvent extraction plant

Brand:

Others

Price ₹

35,00,000.00

| General Details: | |

| Model | Herbal solvent extraction plant |

| Material | SS |

| Automation Grade | SEMI |

| Voltage | 415 |

| Driven Type | Electrical |

| Capacity | Customization |

| Usage/Application | Herbal Extraction |

| Power Source | Electrical |

Industrial solvent extraction system

Brand:

Others

Price ₹

25,00,000.00

| General Details: | |

| Model | Solvent extraction plant |

| Material | SS |

| Automation Grade | SEMI |

| Voltage | 415 |

| Driven Type | Electrical |

| Capacity | Customization |

| Usage/Application | Herbal Extraction |

| Power Source | Electrical |

Continuous solvent extraction plant

Brand:

Others

Price ₹

85,00,000.00

| General Details: | |

| Model | Continuous solvent extraction plant |

| Material | SS |

| Automation Grade | SEMI |

| Voltage | 415 |

| Driven Type | Electrical |

| Capacity | Customization |

| Usage/Application | Herbal Extraction |

| Power Source | Electrical |

Solvent extraction plant suppliers in India

Brand:

Others

Price ₹

25,00,000.00

| General Details: | |

| Model | Solvent extraction plant suppliers in India |

| Material | SS |

| Others: | |

| Available | In Stock |

| Business Type | Manufacturer, Supplier |

| Condition | Brand New |

| Country of Origin | Made in India |

| Features | Solvent recovery, low energy |

| I Deal In | New Only |

| Minimum Quantity Order | 1 Unit |

Solvent extraction plant

Brand:

Others

Price ₹

50,00,000.00

| General Details: | |

| Model | Solvent extraction plant |

| Material | SS |

| Automation Grade | SEMI |

| Voltage | 415 |

| Capacity | Customization |

| Usage/Application | Herbal Extraction |

| Power Source | Electrical |

Frangipani Extraction Plant

Brand:

Others

Price ₹

50,00,000.00

| General Details: | |

| Model | Solvent extraction plant |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 415 |

| Driven Type | Electrical |

| Motor | yes |

| Capacity | Customization |

| Usage/Application | Herbal Extraction |

| Machine Type | Yes |

| Power Source | Electrical |

| Design Type | yes |

| Thickness Of Flakes | yes |

| Pressure | yes |

| Temperature Range | yes |

| Others: | |

| Brand | Mechotechllp |

Coffee Robusta (Coffea canephora) Herbal Extraction Plant

Brand:

Others

Price ₹

50,00,000.00

| General Details: | |

| Model | Coffee Robusta (Coffea canephora) Herbal Extraction Plant |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 240V |

| Driven Type | Electrical |

| Motor | yes |

| Capacity | Customization |

| Usage/Application | Herbal Extraction |

| Machine Type | Solvent Extraction |

| Power Source | Electric |

| Design Type | yes |

| Thickness Of Flakes | yes |

| Pressure | yes |

| Temperature Range | yes |

| Others: | |

| Brand | MECHOTECH LLP |

Cucumber (Cucumis sativus) Extract

Brand:

Others

Price ₹

45,00,000.00

| General Details: | |

| Model | Cucumber (Cucumis sativus) Extract |

| Material | Stainless Steel |

| Automation Grade | Semi Automatic |

| Voltage | 240V |

| Driven Type | Electrical |

| Motor | yes |

| Capacity | Customization |

| Usage/Application | Herbal Extraction |

| Machine Type | Solvent Extraction |

| Power Source | Electric |

| Design Type | yes |

| Thickness Of Flakes | yes |

| Pressure | yes |

| Temperature Range | yes |

| Others: | |

| Brand | MECHOTECH LLP |