Liquid Extraction Plant

Commercial Liquid - Liquid extraction Plant

Brand:

Others

Price ₹

15,00,000.00

| General Details: | |

| Model | Commercial Liquid - Liquid extraction Plant |

| Material | Yes |

| Capacity | Yes |

| Voltage | Yes |

| Industry Type | Commercial |

| Usage/Application | Yes |

| Others: | |

| Brand | Yes |

| Installation Services | Yes |

| No Of Unit To Be Tested | Yes |

| Size | Yes |

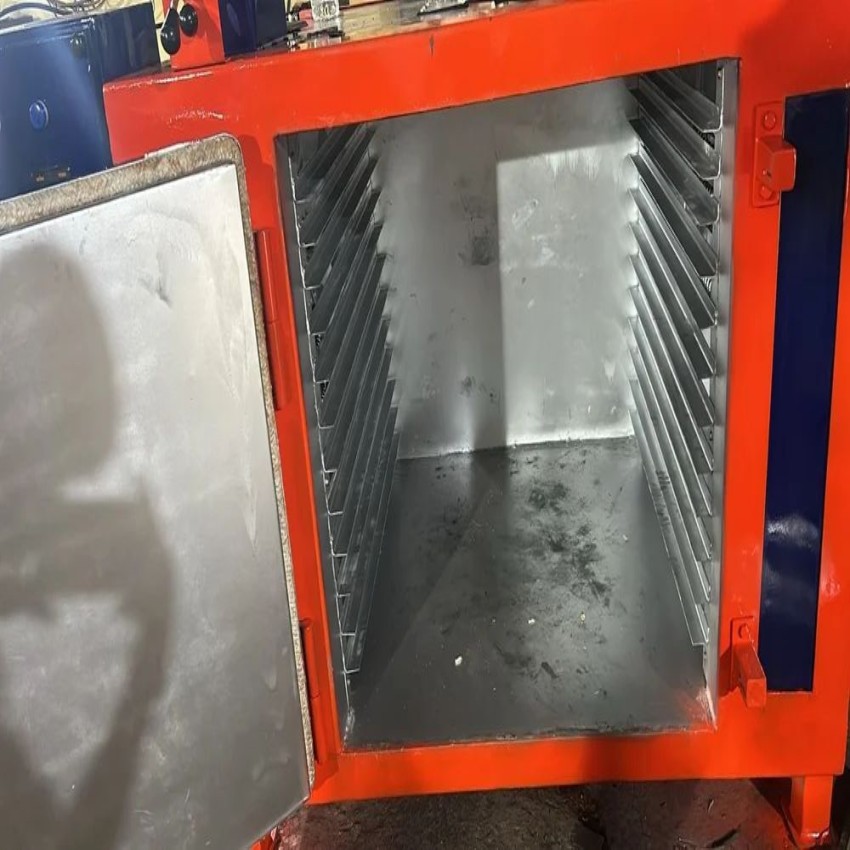

Commercial Solid Liquid extraction Plant

Brand:

Others

Price ₹

10,00,000.00

| General Details: | |

| Model | Commercial Solid Liquid extraction Plant |

| Material | Yes |

| Capacity | Yes |

| Voltage | Yes |

| Industry Type | Commercial |

| Usage/Application | Yes |

| Others: | |

| Brand | 50 |

| Installation Services | Yes |

| No Of Unit To Be Tested | Yes |

| Size | Yes |

if you are interested, please fill the below details: