Clove Leaf Oil Distillation Plant, Capacity: 5 TPD

Brand:

Others

Price ₹

1,00,00,000.00

₹1,00,00,000.00

| General Details: | |

| Model | Clove Leaf Oil Distillation Plant, Capacity: 5 TPD |

| Automation Grade | Semi Automatic |

| Frequency | 50Hz |

| Power Source | Electrical And Wood |

| Voltage | 415V |

| Others: | |

| Capacity | 5 TPD |

| Country of Origin | Made in India |

| Recommended Order Quantity | 1 |

Description

A clove leaf oil steam distillation plant is a facility designed to extract essential oil from clove leaves using the steam distillation process. Clove oil is derived from the aromatic leaves of the clove plant (Syzygium aromaticum) and is known for its various medicinal, culinary, and aromatic properties.Here is a description of the key components and processes involved in a typical clove leaf oil steam distillation plant:Raw Material Handling:Clove leaves are harvested from the clove plants and transported to the distillation plant.The leaves need to be fresh to ensure a high-quality oil extraction.Steam Generation:Water is heated to generate steam, which is a crucial component of the distillation process.High-quality steam is essential for efficient extraction of clove oil.Distillation Unit:The distillation unit consists of a distillation chamber or still where the clove leaves are placed.Steam is passed through the clove leaves, causing the essential oil to evaporate.Condensation:The vaporized essential oil along with steam is then condensed back into a liquid form.The condensation process usually takes place in a separate condenser unit.Separation:Since essential oil and water do not mix, the condensed liquid is separated into two layers – the upper layer containing the clove leaf essential oil and the lower layer containing water.Collection:The clove leaf essential oil is then collected from the surface of the separated liquid.The collected oil may undergo additional filtration or refining processes to remove impurities.Storage:The final, purified clove leaf essential oil is stored in appropriate containers.Proper storage conditions, such as cool and dark environments, are maintained to preserve the oil's quality.By-Products Utilization:Residual plant material and water, left after the extraction process, may be used as a source of organic matter or for other purposes.Quality Control:Quality control measures are implemented throughout the process to ensure that the extracted clove leaf oil meets industry standards and customer expectations.Safety Measures:Safety features such as pressure relief valves, temperature monitoring, and emergency shutdown systems are installed to ensure the safety of the plant operators and the facility.A well-designed and efficiently operated clove leaf oil steam distillation plant is crucial for producing high-quality essential oil that can be used in various industries, including pharmaceuticals, cosmetics, aromatherapy, and food. Regular maintenance and adherence to industry standards are essential to ensure the longevity and reliability of the plant.

More Products from Mech O Tech LLP

Turmeric Leaf Oil Distillation Plant, Capacity: 5 TPD

Price ₹

1,07,50,000.00

₹1,07,50,000.00

Mech O Tech LLP Details

| GST | 36ABYFM4488P1ZW |

| Year of Establishment | 2023 |

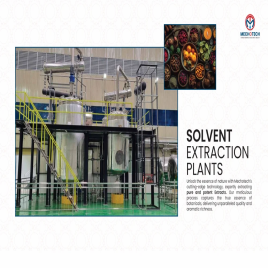

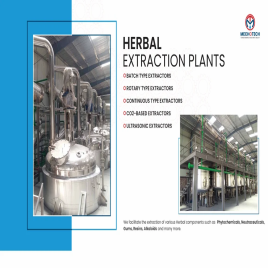

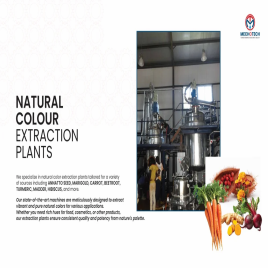

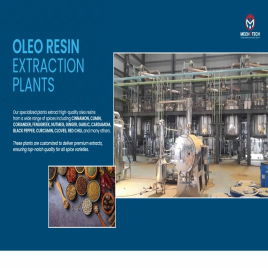

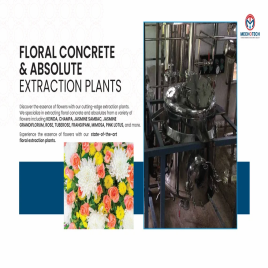

| Nature of Business | MANUFACTURERS OF SOLVENT EXTRACTION PLANTS AND DISTILLATION PLANTS |

| Turnover | 250000000 |

| Legal Status | Limited Liability Company |

if you are interested, please fill the below details: