Annotto / Bixin / Nor Bixin Extraction Plant, Capacity: 10 TPD

Brand:

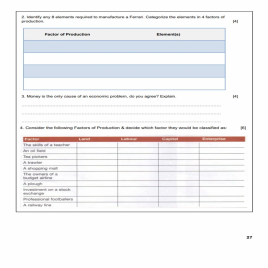

Others

Price ₹

1,00,00,000.00

₹1,00,00,000.00

| General Details: | |

| Model | Annotto / Bixin / Nor Bixin Extraction Plant, Capacity: 10 TPD |

| Material | SS |

| Installation Services | Yes |

| Others: | |

| Capacity | 10 TPD |

| Country of Origin | Made in India |

| Frequency | 50 / 60 HZ |

| Recommended Order Quantity | 1 Plant |

| Power Source | Electrical |

| Usage/Application | Natural Color Extraction |

| Voltage | 415 |

Description

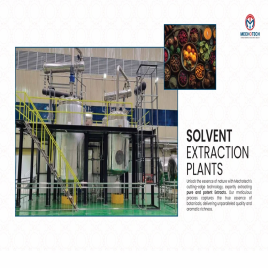

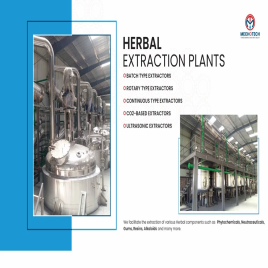

A natural color extraction plant is a facility designed to extract pigments and dyes from various natural sources such as fruits, vegetables, flowers, and other botanical materials. These extracted colors are commonly used in the food, beverage, cosmetic, and pharmaceutical industries as natural alternatives to synthetic dyes.Here's a general description of how a natural color extraction plant might operate:Raw Material Reception: The plant receives shipments of natural sources such as berries, roots, leaves, or other botanical materials. These materials are inspected for quality and then stored in appropriate conditions to maintain their freshness until processing.Cleaning and Preparation: Before extraction, the raw materials need to be cleaned to remove any dirt, debris, or contaminants. Depending on the source, the materials might also require sorting or chopping to ensure uniformity and facilitate the extraction process.Extraction: There are various methods for extracting colors from natural sources, including maceration, pressing, solvent extraction, and steam distillation. The choice of method depends on the type of colorant being extracted and the properties of the source material. For example, water-soluble pigments might be extracted using aqueous methods, while oil-soluble pigments might require solvent extraction.Filtration and Purification: Once the colors are extracted, the crude extract undergoes filtration to remove any solid particles or impurities. It may also undergo purification processes such as centrifugation, chromatography, or membrane filtration to isolate and concentrate the desired color compounds.Stabilization and Preservation: Natural colors can be sensitive to factors such as light, heat, and pH. Therefore, stabilizers and preservatives may be added to the extracted colors to prolong their shelf life and maintain their stability under various conditions.Quality Control: Throughout the extraction and processing stages, quality control measures are implemented to ensure that the colors meet the required standards for purity, potency, and safety. This may involve testing for factors such as color intensity, pH levels, microbial contamination, and heavy metal residues.Packaging and Storage: The extracted colors are packaged into containers suitable for transportation and storage. Packaging materials must be chosen carefully to prevent color degradation and ensure product integrity. The packaged colors are then stored in controlled environments to maintain their quality until they are shipped to customers.Overall, a natural color extraction plant plays a crucial role in producing vibrant, safe, and environmentally friendly colorants for various industries while ensuring compliance with regulatory standards and maintaining high-quality standards throughout the production proces

More Products from Mech O Tech LLP

Turmeric Leaf Oil Distillation Plant, Capacity: 5 TPD

Price ₹

1,07,50,000.00

₹1,07,50,000.00

Clove Leaf Oil Distillation Plant, Capacity: 5 TPD

Price ₹

1,00,00,000.00

₹1,00,00,000.00

Mech O Tech LLP Details

| GST | 36ABYFM4488P1ZW |

| Year of Establishment | 2023 |

| Nature of Business | MANUFACTURERS OF SOLVENT EXTRACTION PLANTS AND DISTILLATION PLANTS |

| Turnover | 250000000 |

| Legal Status | Limited Liability Company |

if you are interested, please fill the below details: