Cinnamon Bark Oil Distillation Plant

Brand:

Others

Price ₹

5,00,000.00

₹5,00,000.00

| General Details: | |

| Model | Cinnamon Bark Oil Distillation Plant |

| Automation Grade | Semi Automatic |

| Frequency | 50 / 60 hz |

| Voltage | 220 / 415 / 440 V |

| Usage/Application | Spice Oil Distillation |

| Others: | |

| Capacity | 10 TPD |

| Country of Origin | Made in India |

Description

A cinnamon bark oil distillation plant is a facility dedicated to extracting essential oil from cinnamon bark through a distillation process. Here's an overview of how such a plant typically operates and the key components involved:1. Raw Material PreparationCinnamon Bark Collection: Cinnamon bark is harvested from cinnamon trees (Cinnamomum verum or Cinnamomum cassia). The bark is usually dried before processing.Preparation: The dried bark is cut into smaller pieces or ground to increase surface area and improve the efficiency of the extraction process.2. Distillation ProcessSteam Distillation: This is the most common method for extracting essential oils. In this process:Loading: The prepared cinnamon bark is placed into a distillation chamber.Steam Generation: Steam is passed through the bark, causing the essential oil to evaporate.Condensation: The steam carrying the essential oil is then cooled in a condenser, where it returns to a liquid state.Separation: The essential oil, which is less dense than water, floats on top of the condensed water and is collected separately.Hydrodistillation: An alternative method where the bark is boiled in water, and the steam containing the oil is condensed and separated.3. Collection and SeparationOil Collection: The essential oil is collected from the top of the water and is often filtered to remove any impurities.Water Separation: The remaining water, known as hydrosol or cinnamon water, may have additional uses or be discarded.4. Quality ControlTesting: The essential oil is tested for purity, concentration, and quality. This can involve chemical analysis using techniques like gas chromatography-mass spectrometry (GC-MS).5. Packaging and DistributionPackaging: The essential oil is packaged in airtight containers to preserve its quality and prevent oxidation.Distribution: The packaged oil is then distributed to various markets, including those for aromatherapy, cosmetics, and flavoring.Additional Considerations:Plant Size and Scale: Distillation plants can vary in size from small-scale artisanal setups to large industrial facilities.Efficiency: The design and operation of the plant can impact the yield and quality of the essential oil produced.Technology: Advances in distillation technology can improve efficiency and quality, including automated systems and energy-efficient processes.

More Products from Mech O Tech LLP

Turmeric Leaf Oil Distillation Plant, Capacity: 5 TPD

Price ₹

1,07,50,000.00

₹1,07,50,000.00

Clove Leaf Oil Distillation Plant, Capacity: 5 TPD

Price ₹

1,00,00,000.00

₹1,00,00,000.00

Mech O Tech LLP Details

| GST | 36ABYFM4488P1ZW |

| Year of Establishment | 2023 |

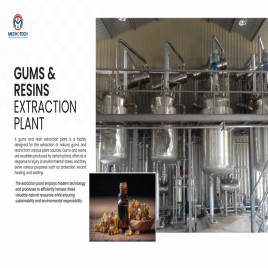

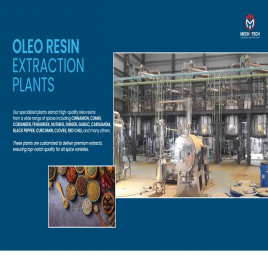

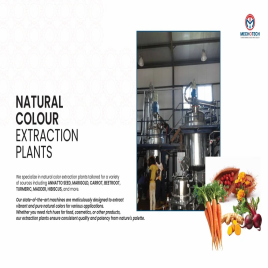

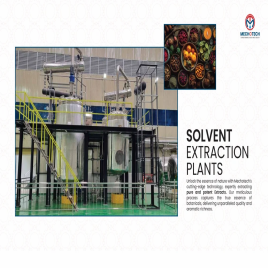

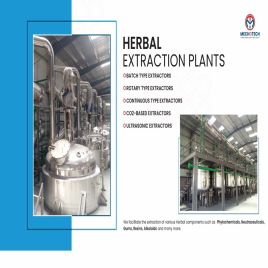

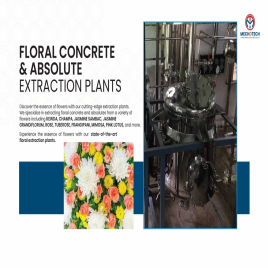

| Nature of Business | MANUFACTURERS OF SOLVENT EXTRACTION PLANTS AND DISTILLATION PLANTS |

| Turnover | 250000000 |

| Legal Status | Limited Liability Company |

if you are interested, please fill the below details: