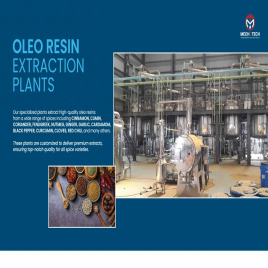

Fenugreek Oleoresin Extraction Processing Plant, Capacity: 100 TPD

Brand:

Others

Price ₹

60,00,000.00

₹60,00,000.00

| General Details: | |

| Model | Fenugreek Oleoresin Extraction Processing Plant, Capacity: 100 TPD |

| Material | Stainless Steel |

| Installation Services | Yes |

| Others: | |

| Automation Grade | Semi Automatic |

| Brand | MECH O TECH |

| Capacity | 100 TPD |

| Country of Origin | Made in India |

| Design Type | TURN KEY |

| Machine Type | TURNKEY PROJECT |

| Power Source | ELECTRIC AND STEAM |

| Usage/Application | FENUGREEK OLEO RESIN EXTRACTION PLANT |

| Voltage | 415 |

Description

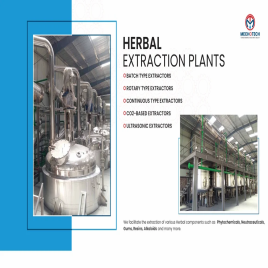

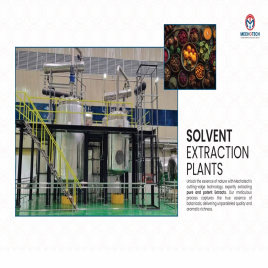

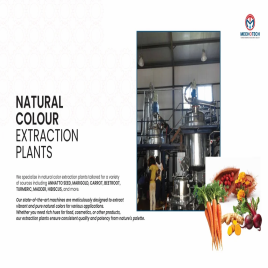

We MECH O TECH LLP, HYDERABAD, INDIA, well known manufacturer for solvent extraction plants for different Oleo Resins.Fenugreek Oleoresin Extraction Plant is a specialized facility designed for the extraction of oleoresin from fenugreek seeds. Fenugreek (Trigonella foenum-graecum) is an herb commonly used in culinary and traditional medicine applications, and its oleoresin is sought after for its various beneficial properties.Here is a general description of a Fenugreek Oleoresin Extraction Plant:Raw Material Handling:The plant begins with the handling of fenugreek seeds. These seeds are carefully inspected, cleaned, and sorted to ensure the quality of the final product.Extraction Process:The extraction of oleoresin is typically done through a solvent extraction method or through supercritical fluid extraction using carbon dioxide. Both methods involve the use of specialized equipment to separate the oleoresin from the fenugreek seeds.Solvent Extraction:In the solvent extraction method, the fenugreek seeds are first ground into a coarse powder. This powder is then mixed with a suitable solvent (such as hexane) to extract the oleoresin. The mixture is then subjected to a series of extraction, distillation, and separation processes to obtain the pure oleoresin.Supercritical Fluid Extraction:In supercritical fluid extraction, carbon dioxide is used as the solvent. The fenugreek seeds are exposed to supercritical CO2, which allows for the efficient extraction of the oleoresin. The advantage of this method is that it avoids the use of potentially harmful solvents, and the extraction process is considered more environmentally friendly.Filtration and Purification:The extracted oleoresin is then subjected to filtration and purification processes to remove any impurities or remaining solvent residues. This ensures the final product meets quality standards.Concentration:The oleoresin may be concentrated to increase its potency and effectiveness. This can be achieved through methods such as vacuum distillation or evaporation.Quality Control:Stringent quality control measures are implemented at various stages of the extraction process to ensure the purity, potency, and safety of the fenugreek oleoresin.Packaging and Storage:The final oleoresin is packaged into suitable containers, adhering to industry standards. Proper labeling is done, indicating essential information such as batch number, production date, and recommended storage conditions.Safety and Compliance:The entire extraction process is carried out in accordance with safety regulations and industry standards. Compliance with food and pharmaceutical safety standards may be crucial, depending on the intended use of the fenugreek oleoresin.Environmental Considerations:Modern extraction plants often incorporate environmentally friendly practices, such as waste management and energy-efficient processes, to minimize the ecological footprint of the production.It's important to note that the specific details of a Fenugreek Oleoresin Extraction Plant may vary based on technological advancements, regulatory requirements, and the scale of production.

More Products from Mech O Tech LLP

Turmeric Leaf Oil Distillation Plant, Capacity: 5 TPD

Price ₹

1,07,50,000.00

₹1,07,50,000.00

Clove Leaf Oil Distillation Plant, Capacity: 5 TPD

Price ₹

1,00,00,000.00

₹1,00,00,000.00

Mech O Tech LLP Details

| GST | 36ABYFM4488P1ZW |

| Year of Establishment | 2023 |

| Nature of Business | MANUFACTURERS OF SOLVENT EXTRACTION PLANTS AND DISTILLATION PLANTS |

| Turnover | 250000000 |

| Legal Status | Limited Liability Company |

if you are interested, please fill the below details: