Ginger Oleo Resin Solvent Extraction Plant, Capacity: 100 TPD

Brand:

Others

Price ₹

10,00,000.00

₹10,00,000.00

| General Details: | |

| Model | Ginger Oleo Resin Solvent Extraction Plant, Capacity: 100 TPD |

| Material | Stainless Steel |

| Installation Services | Yes |

| Others: | |

| Automation Grade | Semi Automatic |

| Brand | MECH O TECH LLP |

| Capacity | 100 TPD |

| Frequency | 50Hz |

| Recommended Order Quantity | 1 Piece |

| Power Source | Electric |

| Voltage | 220V |

Description

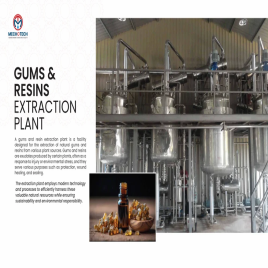

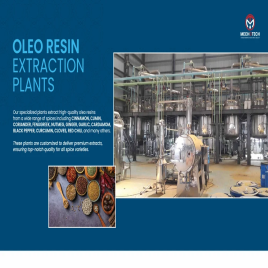

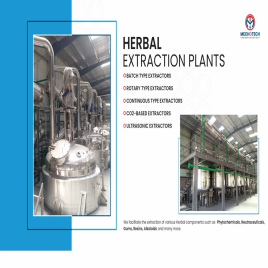

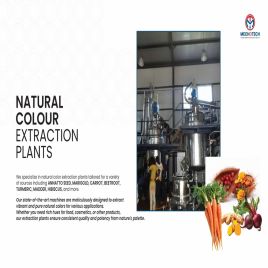

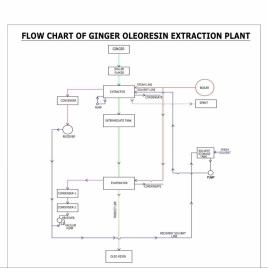

A Ginger Oleoresin Extraction plant is designed to extract oleoresin from ginger rhizomes. Oleoresins are concentrated extracts that contain both essential oils and oleoresin components, providing a more potent flavor and aroma than dried ginger. Here's an overview of the process and components involved in such a plant:

1. Raw Material Preparation

Ginger Rhizome Collection: Fresh ginger rhizomes are sourced from suppliers. They are usually cleaned to remove soil and impurities.

Processing: The cleaned ginger is then sliced or ground to increase surface area and facilitate better extraction.

2. Extraction Process

Solvent Extraction: This is a common method for extracting oleoresin. The process involves:

Maceration: The ground ginger is soaked in a solvent (such as hexane or ethanol) to dissolve the oleoresin.

Filtration: The mixture is filtered to remove solid particles, leaving behind a solution containing the oleoresin.

Solvent Removal: The solvent is evaporated from the solution, usually through distillation or evaporation, leaving behind a concentrated oleoresin.

CO2 Supercritical Extraction: An advanced method where CO2 is used under high pressure and low temperature to extract the oleoresin. This method is efficient and retains more of the natural properties of the ginger.

3. Refinement and Concentration

Concentration: Depending on the desired concentration, the oleoresin may be further concentrated or blended with other ingredients.

Purification: Additional purification processes may be employed to remove any residual solvents or impurities.

4. Quality Control

Testing: The oleoresin undergoes rigorous testing to ensure it meets quality standards. Tests can include:

Chemical Composition: Analysis to ensure the right balance of active compounds.

Microbial Testing: To check for contamination.

Sensory Evaluation: Assessing aroma and flavor.

5. Packaging and Distribution

Packaging: The oleoresin is packaged in airtight, often amber-colored containers to protect it from light and oxidation.

Additional Considerations:

Plant Size and Scale: The scale of the plant can range from small, artisanal setups to large industrial facilities.

Efficiency: Modern extraction technologies and optimized processes can improve yield and quality.

More Products from Mech O Tech LLP

Turmeric Leaf Oil Distillation Plant, Capacity: 5 TPD

Price ₹

1,07,50,000.00

₹1,07,50,000.00

Clove Leaf Oil Distillation Plant, Capacity: 5 TPD

Price ₹

1,00,00,000.00

₹1,00,00,000.00

Mech O Tech LLP Details

| GST | 36ABYFM4488P1ZW |

| Year of Establishment | 2023 |

| Nature of Business | MANUFACTURERS OF SOLVENT EXTRACTION PLANTS AND DISTILLATION PLANTS |

| Turnover | 250000000 |

| Legal Status | Limited Liability Company |

if you are interested, please fill the below details: