Kattha Or Catecheu Manufacturing Plant

Brand:

Others

Price ₹

50,00,000.00

₹50,00,000.00

| General Details: | |

| Model | Kattha Or Catecheu Manufacturing Plant |

| Material | SS304 / 316 |

| Installation Services | Yes |

| Others: | |

| Automation Grade | Semi Automatic |

| Capacity | 10 TPD |

| Frequency | 50Hz |

| Power Source | Electrical & Steam |

| Usage/Application | Katha Extraction |

| Voltage | 415V |

Description

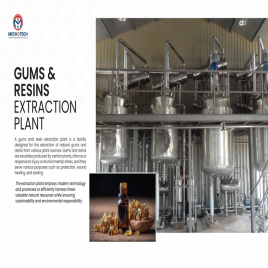

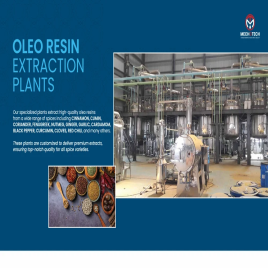

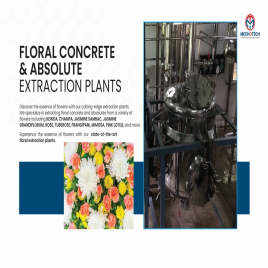

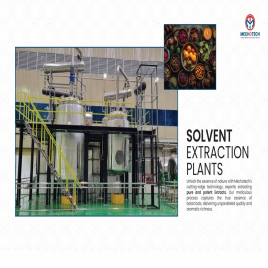

A Catacheu solvent extraction plant is a facility designed for the extraction of valuable compounds or substances from raw materials using a solvent-based process. This type of plant is commonly employed in various industries, including the oil and gas, pharmaceutical, food, and chemical industries.Here is a general description of a Catacheu solvent extraction plant:Raw Material Intake:The process begins with the intake of raw materials containing the desired substances to be extracted. These raw materials can vary widely depending on the industry, but examples include oilseeds, herbs, or other plant materials.Preparation and Pretreatment:The raw materials undergo preparation and pretreatment to enhance the efficiency of the extraction process. This may involve cleaning, grinding, or other methods to break down the raw materials and expose the targeted compounds.Solvent Selection:A suitable solvent is selected based on the specific properties of the target compounds. Common solvents include hexane, ethanol, or supercritical fluids.Extraction Process:The prepared raw materials are then subjected to the solvent extraction process. This typically involves contact between the raw materials and the solvent, allowing the solvent to dissolve and extract the desired compounds. The extraction may take place in a series of extraction vessels or columns.Separation of Extracted Solution:The mixture of solvent and extracted compounds is separated from the remaining solid residue. This separation is often achieved through filtration or other separation techniques.Solvent Recovery:The solvent is then recovered from the extracted solution for reuse in the process. This step is crucial for minimizing waste and reducing the environmental impact of the extraction process.Product Refinement:The extracted solution undergoes further processing to refine and concentrate the desired compounds. This may involve additional separation or purification steps.Final Product Storage:The final product is then stored in appropriate containers, ready for distribution or further proce

More Products from Mech O Tech LLP

Turmeric Leaf Oil Distillation Plant, Capacity: 5 TPD

Price ₹

1,07,50,000.00

₹1,07,50,000.00

Clove Leaf Oil Distillation Plant, Capacity: 5 TPD

Price ₹

1,00,00,000.00

₹1,00,00,000.00

Mech O Tech LLP Details

| GST | 36ABYFM4488P1ZW |

| Year of Establishment | 2023 |

| Nature of Business | MANUFACTURERS OF SOLVENT EXTRACTION PLANTS AND DISTILLATION PLANTS |

| Turnover | 250000000 |

| Legal Status | Limited Liability Company |

if you are interested, please fill the below details: