Tulsi Oil Distillation Plant, Capacity: 10 TPD

Brand:

Others

Price ₹

1,30,20,000.00

₹1,30,20,000.00

| General Details: | |

| Model | Tulsi Oil Distillation Plant, Capacity: 10 TPD |

| Automation Grade | Semi Automatic |

| Frequency | 50 HZ |

| Power Source | ELECTRICAL |

| Voltage | 220 V |

| Usage/Application | TULSI OIL DISTILLATION PLANT |

| Others: | |

| Capacity | 10 TPD |

| Country of Origin | Made in India |

| Recommended Order Quantity | 1 |

Description

A steam distillation plant for extracting tulsi oil would typically involve several components and processes. Here's a general description of how such a plant might operate:Tulsi Cultivation: Tulsi (Holy Basil) would be cultivated on a suitable agricultural land. The quality and yield of the oil largely depend on the species of tulsi, soil quality, climate, and cultivation practices.Harvesting: Once the tulsi plants have reached maturity, they are harvested. The timing of harvesting is crucial as it affects the oil yield and quality.Preparation for Distillation: After harvesting, the tulsi plants are brought to the distillation facility. They are usually chopped or crushed to facilitate the release of essential oils during the distillation process.Steam Distillation: The chopped tulsi material is placed in a distillation chamber or vessel. Steam is then passed through the plant material. The heat of the steam causes the essential oils to evaporate from the plant material.Condensation: The steam carrying the essential oil vapors is then cooled down in a condenser. This condensation process causes the steam to turn back into water, leaving behind the essential oil, which separates due to its immiscibility with water.Separation: Since essential oils are lighter than water, they float on top of the condensed water. The collected mixture is then separated, usually through a separator or a series of decantation steps.Filtration and Purification: The separated essential oil might undergo filtration to remove any remaining plant material or impurities, ensuring a pure and high-quality product.Storage and Packaging: The distilled tulsi oil is stored in appropriate containers that prevent degradation due to light, heat, or air. Once adequately stored, it is packaged into bottles or containers for distribution and sale.By-Product Utilization: Any leftover plant material or spent steam might be used for composting or as feed for animals, ensuring minimal waste in the production process.Quality Control: Throughout the process, quality control measures are implemented to ensure that the final product meets the required standards in terms of purity, aroma, and potency.Regulatory Compliance: The entire process needs to comply with relevant regulations and standards regarding the production, labeling, and sale of essential oils.The specifics of the distillation plant can vary depending on factors such as scale of production, available technology, and desired quality of the final product. However, these steps provide a general overview of the process involved in steam distillation for extracting tulsi oil.

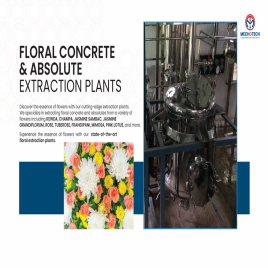

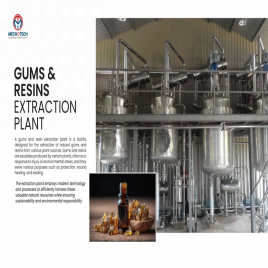

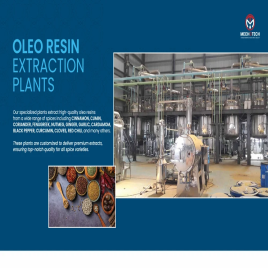

More Products from Mech O Tech LLP

Turmeric Leaf Oil Distillation Plant, Capacity: 5 TPD

Price ₹

1,07,50,000.00

₹1,07,50,000.00

Clove Leaf Oil Distillation Plant, Capacity: 5 TPD

Price ₹

1,00,00,000.00

₹1,00,00,000.00

Mech O Tech LLP Details

| GST | 36ABYFM4488P1ZW |

| Year of Establishment | 2023 |

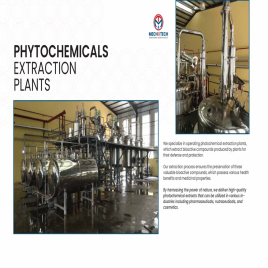

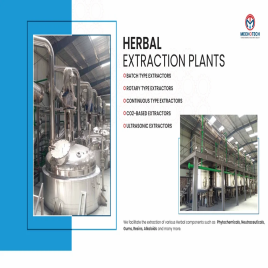

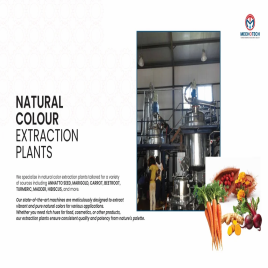

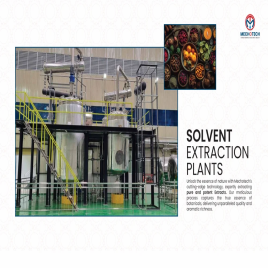

| Nature of Business | MANUFACTURERS OF SOLVENT EXTRACTION PLANTS AND DISTILLATION PLANTS |

| Turnover | 250000000 |

| Legal Status | Limited Liability Company |

if you are interested, please fill the below details: