Vetiver Essential Oil Distillation Unit, Capacity: 50 TPD

Brand:

Others

Price ₹

1,25,00,000.00

₹1,25,00,000.00

| General Details: | |

| Model | Vetiver Essential Oil Distillation Unit, Capacity: 50 TPD |

| Automation Grade | Semi Automatic |

| Frequency | 50 Hz |

| Voltage | 220V |

| Usage/Application | Vetiver Essential Oil Steam Distillation Plant |

| Others: | |

| Capacity | 50 TPD |

| Country of Origin | Made in India |

| Recommended Order Quantity | 1 |

Description

A vetiver essential oil steam distillation plant typically consists of several key components and follows a specific process to extract the oil from the vetiver roots. Here's a general description of how such a plant might be set up:Raw Material Handling: The process begins with the reception of vetiver roots. These roots are typically harvested and cleaned before being sent to the distillation plant.Steam Generation: Steam is generated in a boiler. This steam will be used to pass through the vetiver roots in the distillation chamber to extract the essential oil.Distillation Chamber: The cleaned vetiver roots are loaded into a distillation chamber. This chamber is designed to withstand high temperatures and pressure.Steam Injection: Steam from the boiler is injected into the distillation chamber. The high-temperature steam helps release the essential oil from the vetiver roots.Condensation: As the steam passes through the vetiver roots, it carries the essential oil vapor with it. The steam, along with the essential oil, then enters a condenser, where it is cooled and condensed back into a liquid.Separation: The condensed liquid, consisting of water and vetiver essential oil, undergoes separation. Since oil is lighter than water, it floats on top of the condensed water and can be easily separated.Collection: The vetiver essential oil is collected from the surface of the condensed liquid. It's then transferred to storage containers.By-Products: Some distillation plants may also recover by-products such as hydrosols or floral waters during the condensation process. These can also be collected and used for various purposes.Quality Control: Throughout the process, quality control measures are implemented to ensure the purity and potency of the extracted vetiver essential oil.Packaging: Once the essential oil is collected and quality-checked, it is packaged into containers suitable for storage and distribution.This is a basic overview of the process involved in a vetiver essential oil steam distillation plant. The exact setup and equipment may vary depending on factors such as scale, technology used, and specific requirements of the manufacturer.

More Products from Mech O Tech LLP

Turmeric Leaf Oil Distillation Plant, Capacity: 5 TPD

Price ₹

1,07,50,000.00

₹1,07,50,000.00

Clove Leaf Oil Distillation Plant, Capacity: 5 TPD

Price ₹

1,00,00,000.00

₹1,00,00,000.00

Mech O Tech LLP Details

| GST | 36ABYFM4488P1ZW |

| Year of Establishment | 2023 |

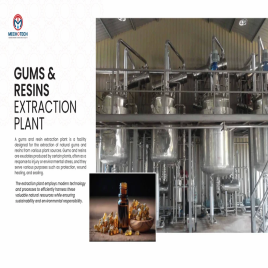

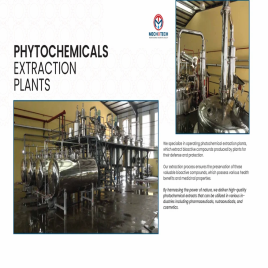

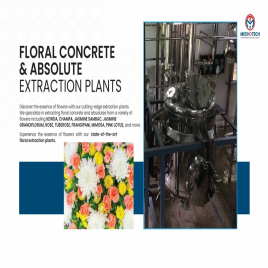

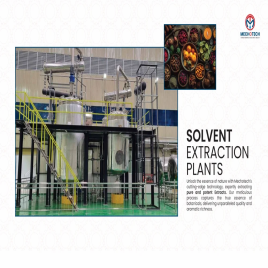

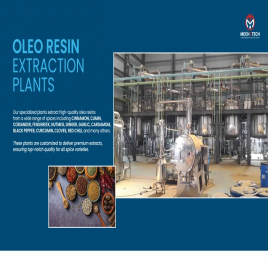

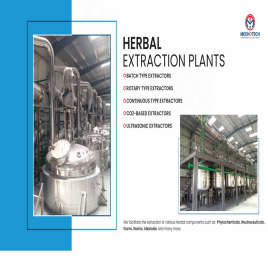

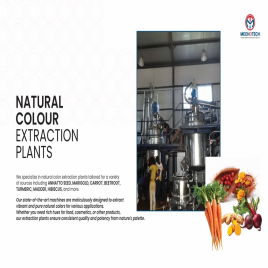

| Nature of Business | MANUFACTURERS OF SOLVENT EXTRACTION PLANTS AND DISTILLATION PLANTS |

| Turnover | 250000000 |

| Legal Status | Limited Liability Company |

if you are interested, please fill the below details: